High-end gas turbine analysis services feature heavily in our March newsletter

Our high-end gas turbine analysis services are being showcased in this months newsletter, ranging from advanced CFD and thermal assessments to rotor-dynamic investigations.

As well as the focus on the above services, this months newsletter includes interesting updates on some of our complex metallic and composite design projects as well as information on our recent JOSCAR approval.

We hope you enjoy the read!

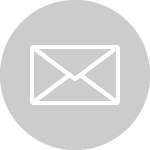

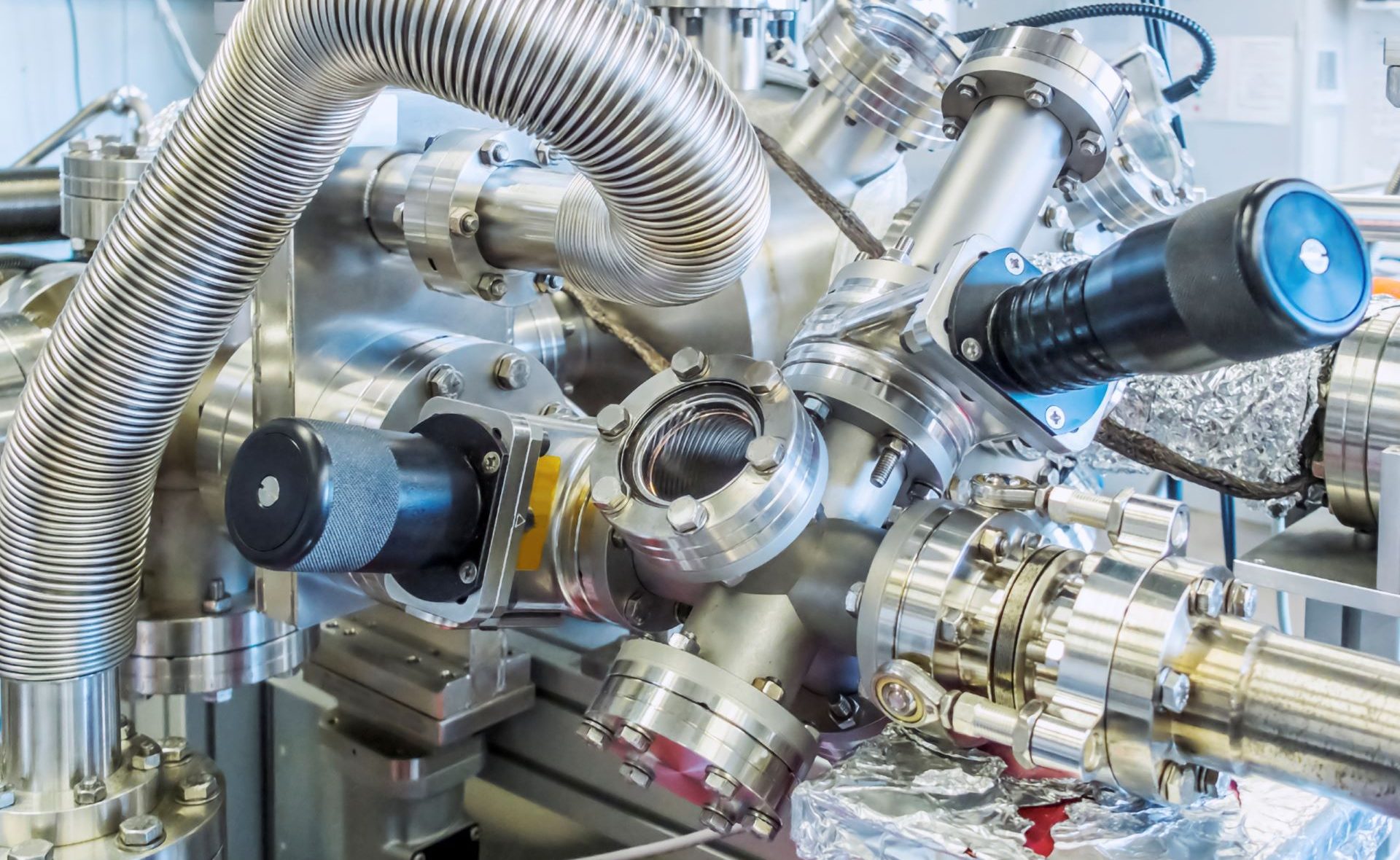

Gas turbine ventilation flow analysis

We have an extensive capability in ventilation flow CFD, suitable for examining the dilution of potential fuel gas leaks under fault conditions, for tightly packaged industrial Gas Turbines. This capability being an important inclusion in our arsenal of high-end gas turbine analysis services. Flow models include buoyancy and natural convection thermal effects, driven by the hot elements of the Gas Turbine, as pictured here.

Applicable industries are marine propulsion, portable packaged gas turbine units and much more…

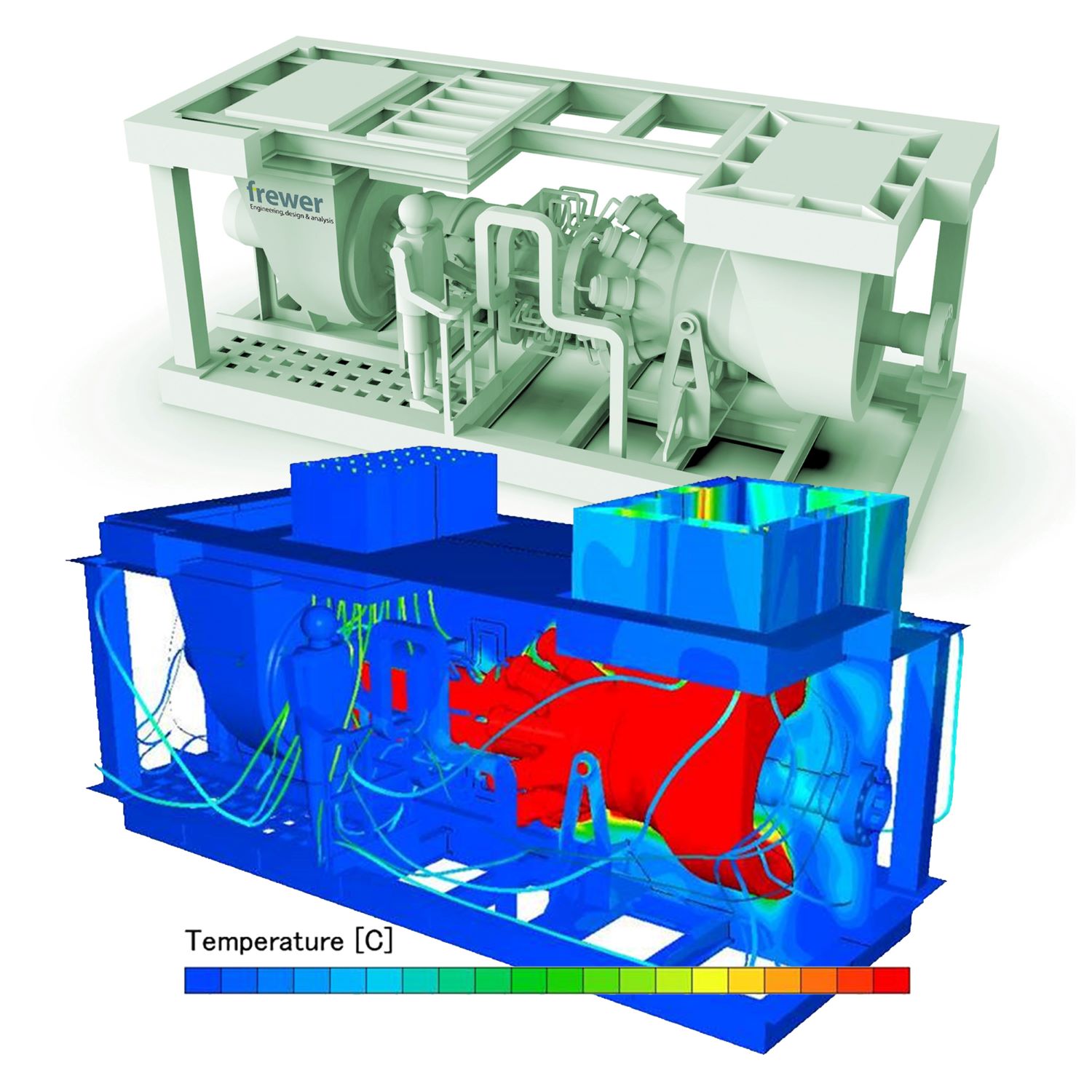

Rotor-dynamic analysis update

Our analysis team are using a mixture of Finite Element Analysis (FEA) and bespoke analysis tools to develop a solution to one of our customers rotor-dynamic requirements. This analysis is to assess an impeller system that is under development for future helicopter propulsion.

Our rotor-dynamic analysis team conduct initial assessments using our calibrated and proven analysis tools to concept a solution, they then move into FEA using MSC NASTRANS Rotor Dynamics software tool. This tool is being utilised on the following analysis types:

- 2D and 3D models

- Blade out response

- Squeeze film dampers

- Critical speeds and whirl frequencies

- Film damper non-linearities

- Rotor imbalance and general excitation

- Rotor rubbing

- Systems with multiple rotors

- Synchronous option (ASYNC)

- Critical speeds with the synchronous option (SYNC)

Being able to model accurately the predicted performance of rotating machinery is key to reducing risk for our clients.

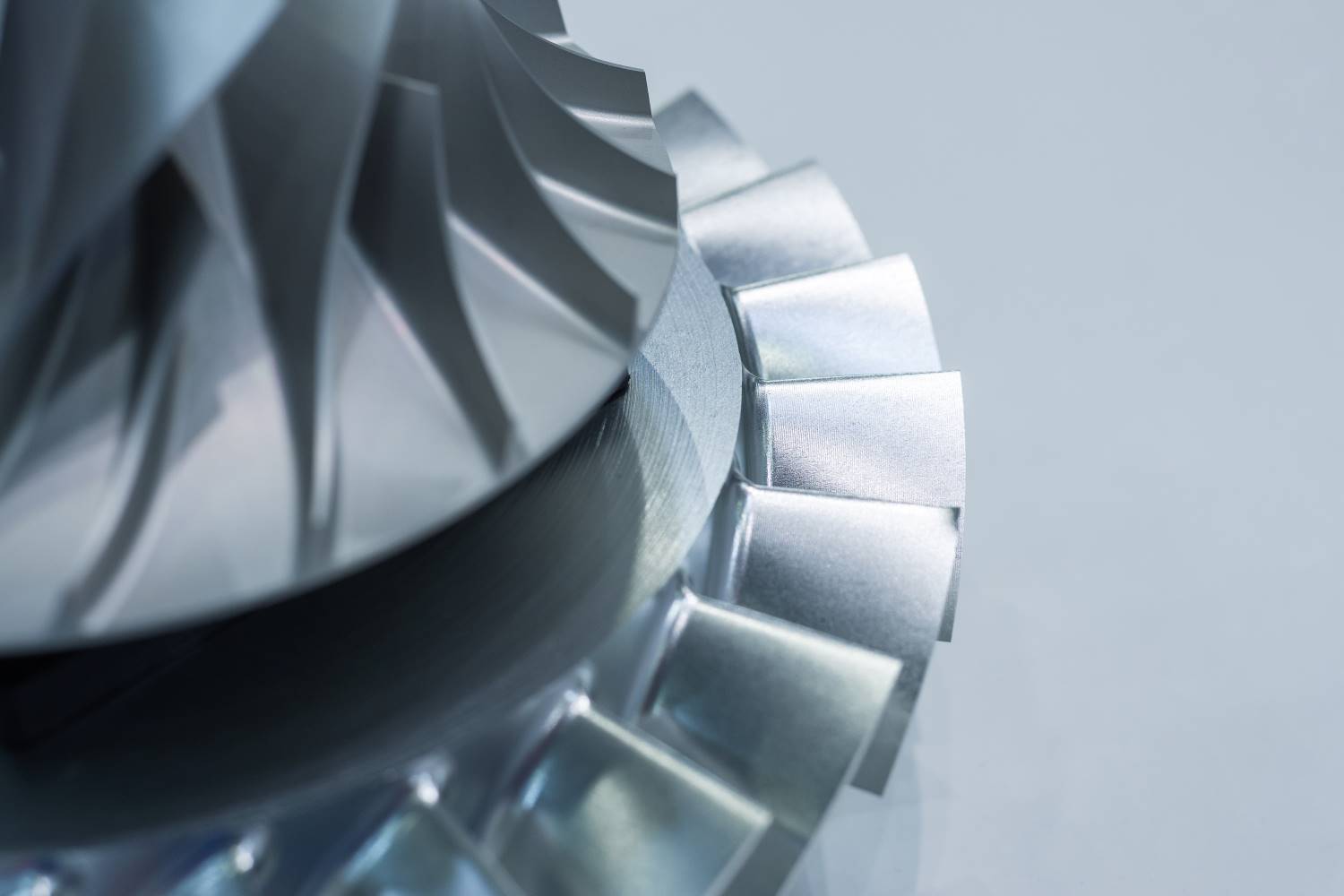

Aerothermal Engineering

Aerothermal engineering has been a “hot” topic at Frewer Engineering in recent years, being one of the most popular high-end gas turbine analysis services we offer. Our engineers are performing aerothermal assessments in a wide range of applications, from gas turbine combustion test rigs to composite aerodynamic panels for aircraft testing. Our extensive knowledge of how the aerothermal response of a system is affected by variations in temperature, pressure and mass flow rate results in a comprehensive service across many industries.

Our aerothermal engineering specialists conduct CFD analyses of the air and gas flows in a system to determine characteristics of the flow, required for subsequent heat transfer analysis. Bespoke heat balance calculation tools are created to conduct initial assessment of the aerothermal behaviour of the components in question. If a project requires design modifications for optimal performance these bespoke calculation tools are used by our multi-skilled design and analysis engineers to optimise the aerodynamic and thermal performance of the structures involved.

Following initial assessments and design iterations, a full thermal CFD model is usually created to provide a comprehensive 3D assessment of the system’s aerothermal response. This is vital to ensure any 3D intricacies are accounted for, such as 3D thermal conduction, especially as these components are often complex in geometry. This complete service allows us to assess the suitability of a system to deal with aerothermal loading and specify cooling techniques, such as heat shielding and air and water cooling, to protect components that may be operating above the melting temperature of the materials. This gives our customers re-assurance when operating their equipment in extreme environments.

Rapid-prototyping to optimise complex mechanism design

We are currently in the process of developing a highly complex mechanical system for one of our customers, who approached us to help turn a theoretical concept into a proven design.

The final metallic version of the mechanism must fit within a tightly enclosed space envelope. In order to de-risk the project, our engineers have been using rapid prototyping methods to demonstrate the solution, replicating the intricate kinematics of our proposed design.

This approach helps give our customer confidence in the direction we are taking, getting hands on with the design early in the development cycle. Our experience of rapid prototyping techniques means we can apply this valuable approach during concept studies, being cognisant of challenges faced using lower fidelity 3D printed parts compared to the final metallic versions.

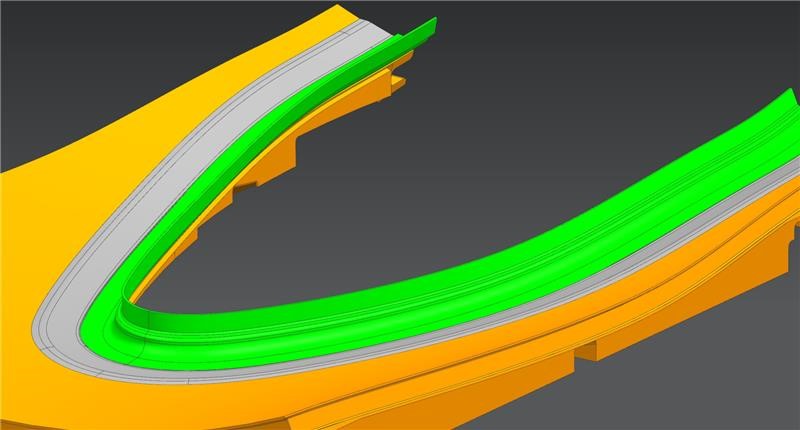

Composites Division develops a novel seal design

Our Advanced Composites Division has been actively engaged in the concept design and analysis of a novel lightweight flexible seal for a gas turbine aero structures project.

The seal is exposed to airstream velocities of 500mph+ and is required to accommodate flexing of between 10 and 30mm with three degrees of freedom. Our solution, based on co-cured aramid and carbon prepreg, is currently undergoing full-scale R&D testing and is already showing promising results for the customer.

Head of the Advanced Composites Division, Matthew Jeffreys said “Co-curing aramid prepreg with carbon prepreg allows us to capitalize on the mechanical properties of each material and match precisely the flexural requirements of the design with a more rigid mounting.”

Dynamic analysis and tuning

Our Advanced Analysis team have been busy using forced and random vibration analysis to assess complex machinery that is being used by one of our US customers based in California for the production of silicone chips.

The project involves the simulation of a variety of vibrational environments, used to inform the equipment designers allowing them to tune the system to achieve acceptable levels of motion etc. Tuning the equipment mounting system springs and other support features is key to obtaining optimal performance.

Our team utilise advanced dynamic software tools from SIEMENS (NASTRAN) to ensure vibrational resilience for our customer.

JOSCAR registration

We are pleased to announce that we are now a JOSCAR approved company!

The JOSCAR approval provides assurance to our clients that we control our business in an approved and secure manner.

This, coupled with our Cyber Essentials Plus approval, that ensures the rebostness of our IT and data control systems (having been tested for attack from outside our organisation), helps to develop our defence engineering service to our customers.

Click Here to subscribe to our newsletter so you never miss an update!