Latest News April 2022

Welcome to the Frewer Engineering latest news April 2022.

This month’s edition includes advancements in our dynamic modelling of composites, modelling secondary air systems, modelling hypersonic flows and more…

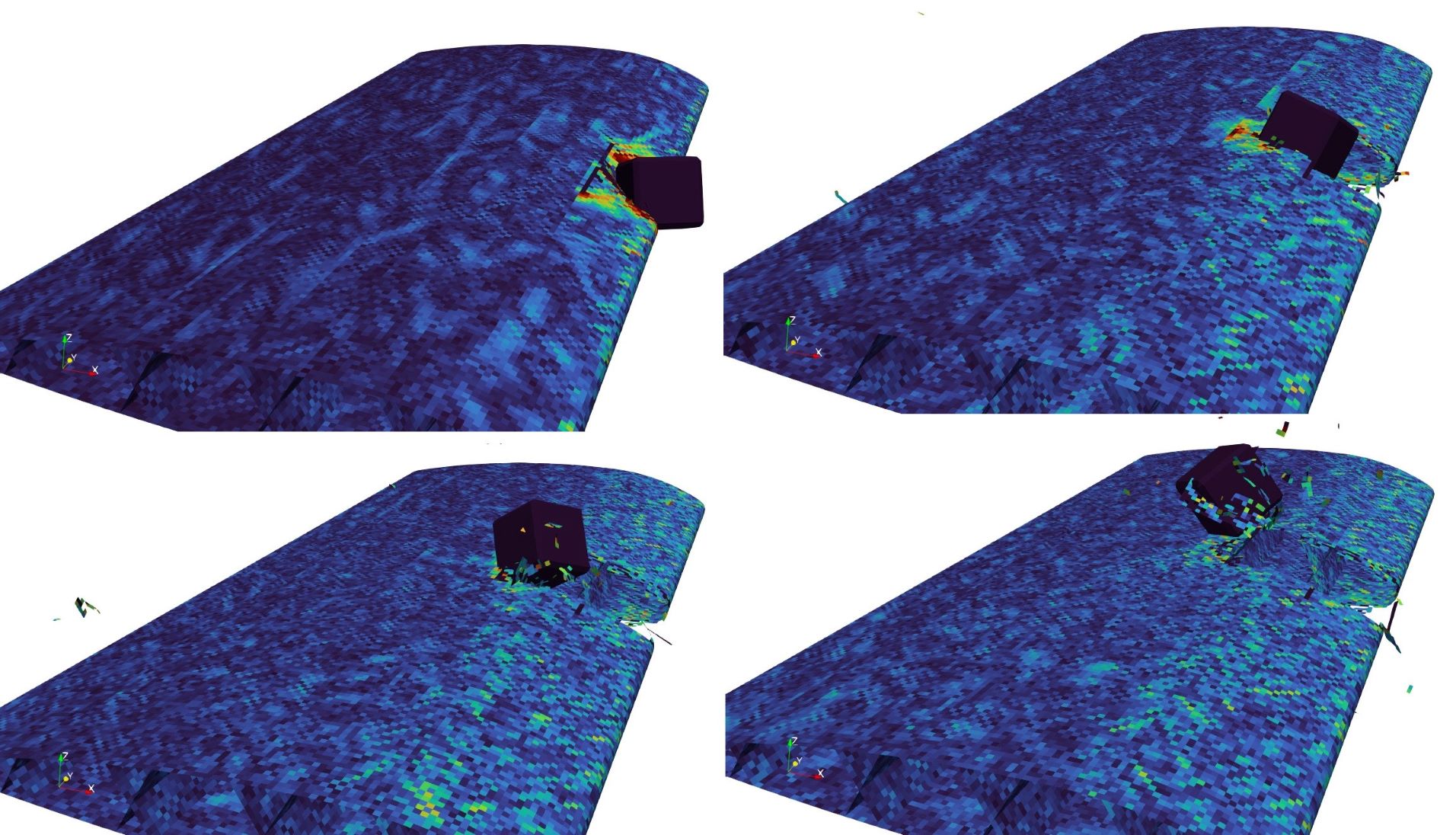

Composite Impact Modelling

This month, our engineers have been combining their significant experience in composite structure analysis with dynamic modelling capabilities to analyse impact on composite wing structures. The team have been using MSC Dytran, an explicit FEA code ideally suited for the analysis of transient events, to model the impact and consequential failure of the composite panels. This analysis helps to support decisions around the design of the composite structure, including the evaluation of layup options and the development of reinforcement solutions for regions of the structure that show a particular sensitivity to the high energy, short duration loads that are caused by fragment impact.

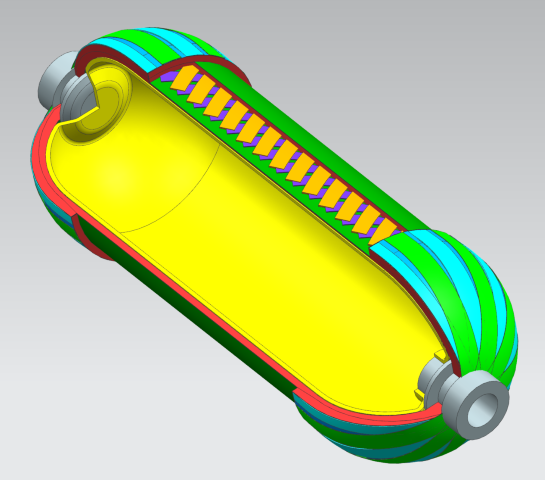

Hydrogen Containment

Safe and effective hydrogen containment is key to unlocking a hydrogen future for sustainable transportation. However, the design and test process for new containment systems with new pressures and novel shapes for specific vehicle applications is costly and time-consuming. Frewer Engineering have developed computational methods which more accurately capture the strength benefits resulting from the filament winding process than ever before. Improved computational fidelity in stress analysis at an earlier stage in the design lifecycle allows for us to reduce the cost of design iterations and potentially reduce the amount of physical testing required.

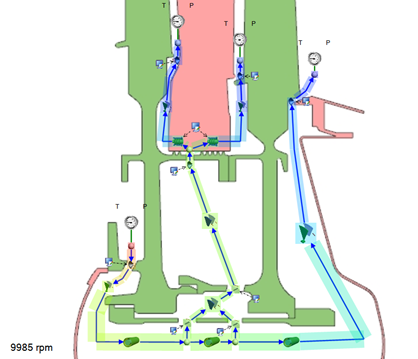

Secondary Air Systems

The image above provides an example of our aero-engine flow modelling capabilities, specifically this shows a flow network analysis of a typical turbine secondary air system (SAS). Using commercial software and the experience of our engineers, Frewer Engineering can model essential SAS components and features such as rotor-stator cavities, labyrinth seals, bleed holes and restrictions. Our analysis tools allow us to predict flow rates, pressures, gas temperatures and more throughout complex flow networks. The results can then be used to build thermal FEA models which predict metal temperatures, thermal expansion and component stresses.

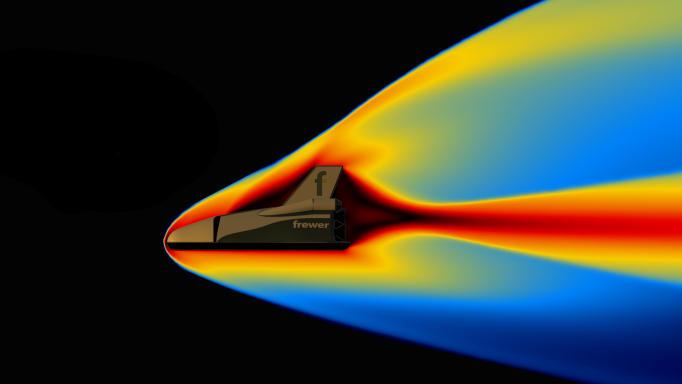

Hypersonic CFD

Considering the limitations of physical testing of aerosurfaces in hypersonic flow, hypersonic computational modelling could be a key to unlocking a new era of aerospace. However, it has continually presented a host of unique challenges, such as accounting for phenomena like molecular dissociation and ionisation. With new RANS hypersonic compressible flow solvers in ScFlow, we can consider the conservation of each chemical species and their associated properties, the influence of molecular vibrational-electron-electronic on temperature and more hypersonic-specific phenomena. Investigating the use of these new RANS solution methods we can harness modelling predictions which inform aerodynamic design in a faster and more cost-effective manner than ever before.

Exhaust Equipment & Nozzle Design

The Frewer Engineering team is active in the field of design & analysis of exhaust systems and high-temperature equipment for gas turbines. Designing high temperature exit nozzles in exotic materials is always a challenge, especially when shape and nozzle throat areas are essential for the creation of specific back pressures which govern gas turbine performance. Our team have specialist capabilities in unrunning these structures to ensure the critical operational geometry is achieved!

Frewer: Going Green

As we continue our journey to towards ISO14001 accreditation, we have updated our environmental policy to be better aligned with our company values. Included in our new policy, we address our carbon emissions, sustainable decision making and governance, alongside integrating environmental considerations into our design processes. Furthermore, to champion our stewardship for the natural world, we are pledging to measure, monitor and publish our environmental performance for full transparency!

Cyclic Symmetry Analysis

Cyclic symmetry analysis facilitates the efficient assessment of full blade sets in gas turbines by simplifying the assembly model into a single, or cluster of blades. In this video, we highlight some of the services that Frewer offers using this analysis, and the benefits in terms of speed and cost that we pass onto our customers. Check out our YouTube channel to see more of our capability videos!