Latest News April 2023

Welcome to the Frewer Engineering latest news April 2023.

Its our 20th year of providing clients with an agile engineering design & analysis consultancy!

Please do get in touch with us to discuss any emerging requirements by following the contact us button at the bottom of the page.

20 years of Agile Engineering Design & Analysis

2023 sees us celebrating our 20th year providing our clients with engineering design and analysis consultancy services! During this time, we have grown from a team of 2, working predominantly in the Aerospace sector, to the larger team we have today providing services across a range of industries, including Aerospace, Marine, Defence and Energy. However, despite this growth and diversification, our core values remain to provide agile, secure and cutting-edge design and analysis services with ever increasing consideration of sustainability in our work. This newsletter reports on our continued growth as we look to take on seven new team members in 2023. We also report on continued investment in IT and Virtual Reality equipment.

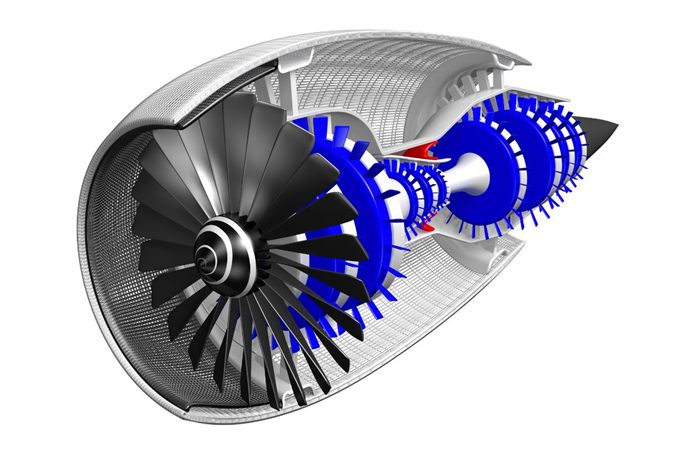

Rotating Machinery Development

Here at Frewer we continue to use and develop our bespoke rotordynamics software tool that interfaces with MSC Nastran to enable rapid, automated model building and analysis. This tool ensures that we can provide the solution that the customer needs, in the time they need it, offering fast turn-around on rotordynamics analysis. Our rotordynamic capabilities include:

- Undamped critical speed maps

- Campbell diagrams and critical speed identification

- Rotor mode shapes

- Forced response analysis

- Torsional response maps

This software tool has been verified for output against other methods and has been proven to work in practice!

Marine Defence Equipment Optimisation

Marine Defence continues to be an active market here at Frewer Engineering. Our engineers operate in the optimisation of composite structures for the marine environment, tuning them for specific strength, stiffness and weight requirements. In addition, we are active in many areas of CFD optimisation, for example in the prediction and reduction of wake and noise associated with specific equipment. Our team are also regularly involved in fluid structure interaction (FSI) analysis and underwater vibration and shock assessments. Our vast experience across the Marine Defence sector allows us to provide an efficient and agile service, no matter the project, from large turnkey projects to smaller individually packaged work streams.

Designs Brought to Life in Virtual Reality

We have recently added Virtual Reality tools to our arsenal, allowing better visualisation of our designs! The equipment allows our team and customers to step into a room with their designs at full scale, to understand the space constraints and accessibility implications. This understanding can then be used to further optimise such designs. The system has already been tested by one of our clients, where it was used to assess the accessibility of components within a complex compressor and turbine test rig we are developing for them.

As reported on previously, our internal IT security protocols, bolstered by our Cyber Essentials Plus certification ensures all our activities protect our customers’ information.

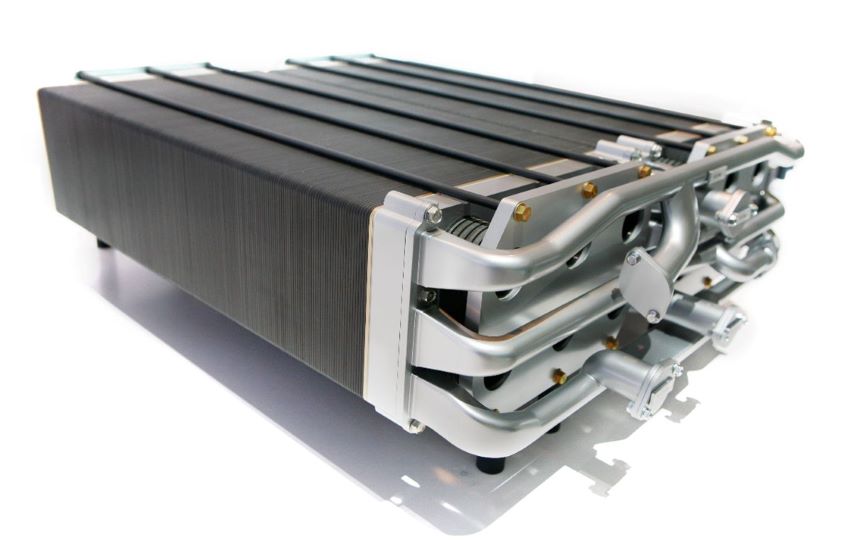

Fuel Cell Systems Digital Twins

Digital Twin Modelling continues to be an area of great interest for our customers, as they require greater accuracy of performance predictions when they come to test new products. Our engineering team are working on the modelling of complete process systems for the trial of new fuel cell installations being developed by one of our customers. The modelling which uses codes such as Python, simulates all elements of what is a complex system to feed and control the fuel cell stacks. Using their understanding of fluids, heat transfer and performance our team are building a digit twin model of the first build and test of the concept.

Combustion Test Equipment Design

In the challenging world of future combustor development, we provide a complete turnkey design and analysis service. This supports our clients who are striving for greater efficiency and hence reduced environmental impact. This often requires pushing the boundaries of combustion conditions, specifically temperature and pressure, to levels beyond the limit of most materials. To meet the requirements of our customers, our engineers regularly deal with high temperature component design, implementing air and water cooling solutions and conducting complete thermo-mechanical models of the structures.

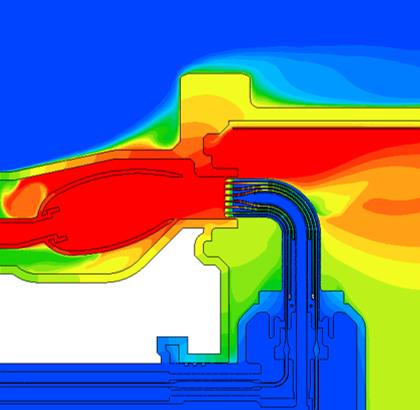

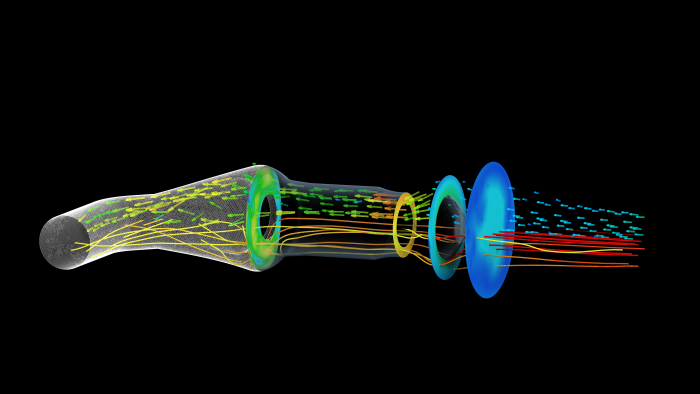

CFD Optimisation of Internal Flows

Our engineers are employing CFD to assess air presentation throughout the gas paths of gas turbine compressor and turbine test equipment, dictating flow quality received by the test rotatives. Our combined design and analysis capabilities allows these analyses to seamlessly shape the mechanical system around the fluid one, optimising pressure loss and flow efficiency in one, and minimising mass in the other. Packaging gas paths into tight spaces is common in both flight & rig systems, but tight bends and rapid expansions cause non-uniformity. Implicit simulations of flow conditioning features like pressure screens, honeycombs & flow straighteners allow us to assess their benefits for bulk flow characteristics, and optimise the number/tuning of devices needed.

Support to Manufacture – A Key Element of Our Customer Service

Our complete turnkey service is a regular feature and involves supporting our clients during manufacture with design changes due to unforeseen issues such as material availability changes. Our design team are acutely aware of Design For Manufacture (DFM), which we consider throughout our projects, working closely with manufacturers to avoid issues further down the line.

Currently our design team are completing refresh training in GD&T to better capture the design intent in manufacture and assembly. This two-day course is being run by Mark Green MSc who is an expert in this field. All design staff will be obtaining certification to the ASME Y14.5-2018 standard. This will ensure our designs are dimensionally controlled through manufacture, increasing the efficiency of the DFM process.

New Starters Bolster our Team

In the coming months we have seven new members of staff joining our team! The new starters will be bolstering the following departments in our engineering consultancy service:

- Computational Fluid Dynamics (CFD)

- Mechanical & Structural Design

- Detailed Design

- Thermal and structural analysis (FEA)

Keep an eye out for more detail on our new members in the following issues of this newsletter…

Investment in Computing Hardware

This month sees us invest heavily in new computing power to enable our engineers to solve customer problems faster. These new machines will be used for seamless development of higher fidelity 3D CAD models along with running complex structural and fluid analyses for our clients. As ever, our customers’ needs test the limits of our available computing power, however, this recent investment allows us to meet and exceed those needs for the foreseeable future. This investment in high speed computing follows on from our recent large scale investment in our intranet system, combining to create an extremely efficient system in use by our engineers!