Latest News May 2020

Impact, Shock & Vibration Analysis is highly active!

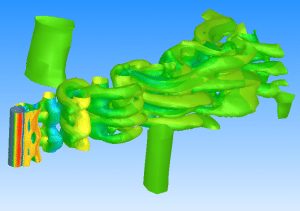

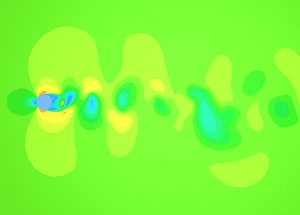

CFD & Fluid Structure Interaction Analysis (FSI) Update – This area continues to grow at pace!

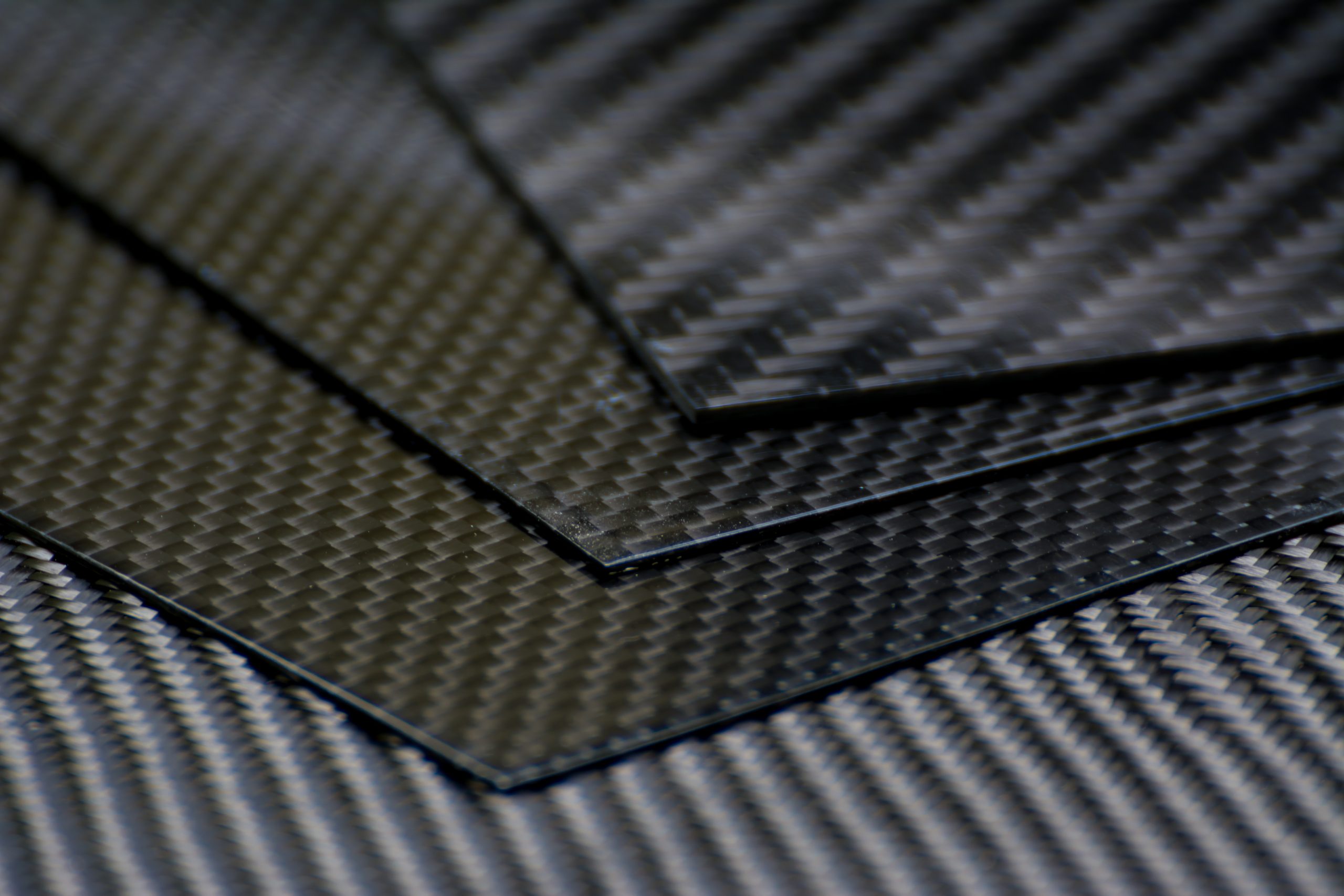

Advanced Composites Division Update

The composite team is also designing lightweight composite panels for a variety of applications where weight saving is critical under very harsh loading conditions. The team is supported by the CFD and advanced analysis team in order to conduct fluid structure interaction investigations.

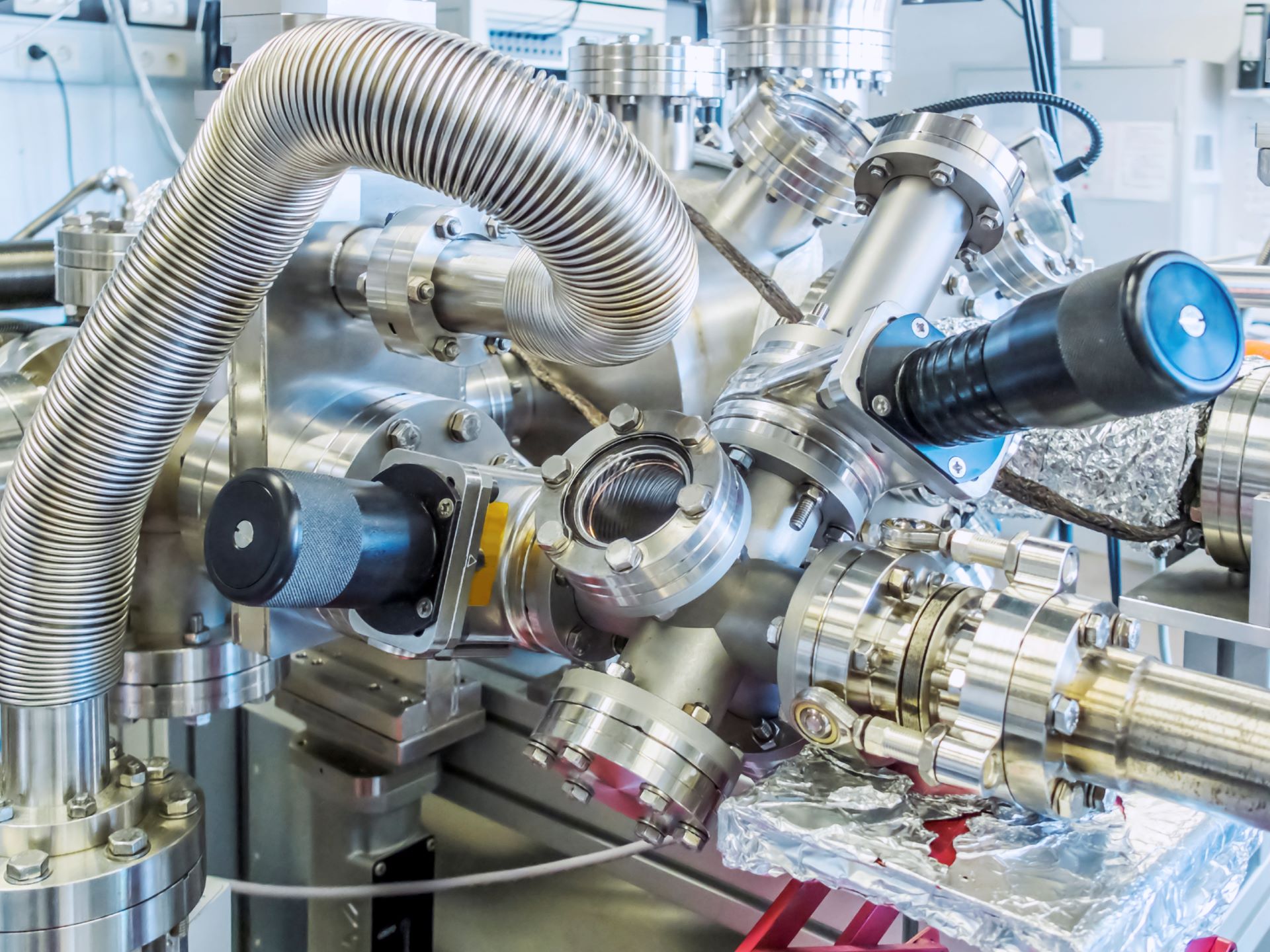

Advanced Engineering Division Update

We are currently designing equipment for the development of future air vehicle propulsion systems. From Jet Nozzles working in very high temperature conditions to gas turbine engine test pylons.

Performing hot to cold or unrunning analysis of loaded shapes to achieve as manufactured shapes that will gain their optimum aerodynamic performance when loaded in service is critical.

Further work is ongoing designing future gas turbine combustion test equipment which, will enable our customers to test much cleaner and more efficient combustion equipment, leading to lower emissions and a cleaner sky. Projects involving very high temperature materials and complex fabrications is usual business to this team.

Defence Activities Update

Our Defence activities remain robust and highly active, servicing the surface marine defence and sub surface systems operations. We are providing a wide range of services to the Defence industry, including composite component design, shock and vibration studies and CFD analysis.

COVID-19 Virus Update

In order to protect our employees, customers and the rest of the UK, all of our employees remain working from home. Our ban on all travel remains in place unless risk assessed and vital.

We have heavily invested in all new laptops where required for our staff, along with bespoke remote software tools. Our software suppliers, SIEMENS, PTC and MSC have provided us with free keys to enable our team be fully functional whilst working remotely – we are extremely grateful for this help through these challenging times.

Its business as usual on all fronts for us.