Latest News May 2022

Welcome to the Frewer Engineering latest news May 2022.

This month’s edition includes our involvment in Hydrogen energy and Gas Turbine development projects as well as updates on our latest investments in staff, equipment and internal processes…

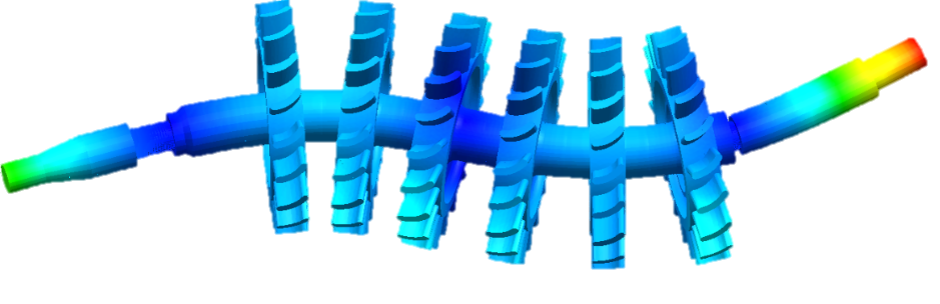

Hydrogen Development

Use of Hydrogen for a variety of purposes has become a hot topic of late, here at Frewer we are keen to use our expertise to aid the expansion of Hydrogen use as an alternative to fossil fuels. Our team have already been involved in enhancements in composite filament winding technology with applications for Hydrogen containment and are supporting R&D and production activities for Hydrogen fuel cells development. With specialists in composite structures, thermal and fluids analysis, test facilities design and much more, we are well placed to support this fast-growing area of engineering!

Completion of Gas Turbine Nozzle Project

We have recently completed a two-year programme of work to design, analyse and support the manufacture of a hot nozzle for a new large aircraft engine. Use of our specialist knowledge in designing high-temperature equipment is crucial to ensure structural integrity along with meeting the complex shape requirements. Due to the extreme temperature environment the nozzle is exposed to, exotic Nimonic alloys were specified in the design, assessment of these alloys is second nature to our thermal design team. Hot to cold analysis is a critical step in this assessment process, to define the cold manufacturing shape that will produce the desired hot shape in operation. We are very pleased to have been involved in the successful delivery of these vital exhaust components!

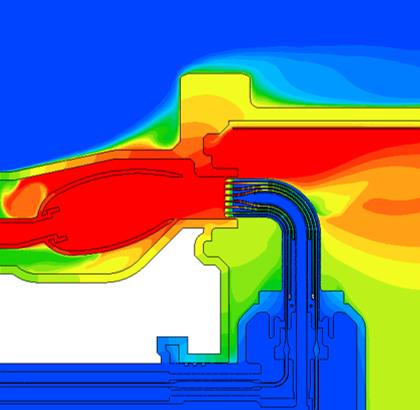

Thermal Modelling at Frewer Engineering

Frewer Engineering’s thermal modelling capabilities have gone from strength to strength over the past few years. Our experts, Martha Cooper and Eddie Pink, have led multiple thermal assessment projects for our customers and in the process disseminated their unique know-how to the wider team. This has created a team of up-and-coming thermal specialists, who are combining the knowledge learnt from our experts and the ever-increasing performance of analysis software. From analysis of high temperature gas turbine equipment to thermal and ventilation assessments of R&D equipment, the team are utilising complex CFD models and programming to produce thermal design solutions for our customers.

High-Speed Rotating Equipment

High-speed rotating machinery is a particular area of expertise here at Frewer Engineering. Over the years we have designed and analysed a variety of equipment for testing components under high-speed rotations, most predominantly equipment used in the development of aircraft engine fan, turbine and compressor blades. Our team have a vast range of capabilities in this area, including rotordynamics, blade un-running and non-linear bending assessments, accounting for normal operational loading as well as extremely large fault case loading. When it comes to high-speed rotating equipment, we offer the safe pair of hands to deliver a robust and reliable solution to challenging customer requirements.

CFD Service Update

At Frewer Engineering, we support our partners with advanced CFD & thermofluid analysis. With a full-suite of multi-physics software in our arsenal, we can employ the right methods to suit the resolution and schedule for your individual requirements. Using a range of techniques, we cover the modelling of coupled thermal flow in complex pipe work systems, through to aerodynamic efficiency assessments and geometry optimisation or even fluid-structure interaction analysis. Our engineers offer full integration of these capabilities with iterative design development as part of large turnkey design projects as well as stand-alone analysis work packages. Our many years of expertise give you the authority on successful fluid-facing design.

Summer Investments: Staff and Equipment

This summer we will be seeing investment in new staff and new equipment. Harry Buttle and Benjamin Luxmoore will shortly be joining us, bringing with them experience in the design and analysis of composite components, and UAV test equipment. Both have an in-depth appreciation for design for manufacture (DFM) from their previous experience, which will fit well with our current team who work closely with our manufacturing partners to ensure DFM is considered throughout a project. In terms of equipment, we are investing in a new server and high-speed switches which will result in increased security and faster processing speeds, improving the efficiency of the services we provide to our customers.

Company Processes: Quality and Sustainability

Our customers can be assured in the robustness of our management system after having passed our three-year re-certification audit to BSI 9001:2015 this month! This international standard certifies the quality of our operations, providing confidence in our services to industry. In addition, we are currently working towards certification to ISO14001, to ensure our processes not only meet quality standards but also consider sustainability at the core. As part of this process we have provided further information on our commitments to sustainability on our website, click the button below to visit our sustainability page!