Latest News November 2022

Welcome to the Frewer Engineering latest news November 2022.

In this issue we report exciting developments in our business across all three divisions: Advanced Engineering, CFD & Thermal and Composite Structure Design.

Renewable Energy Update

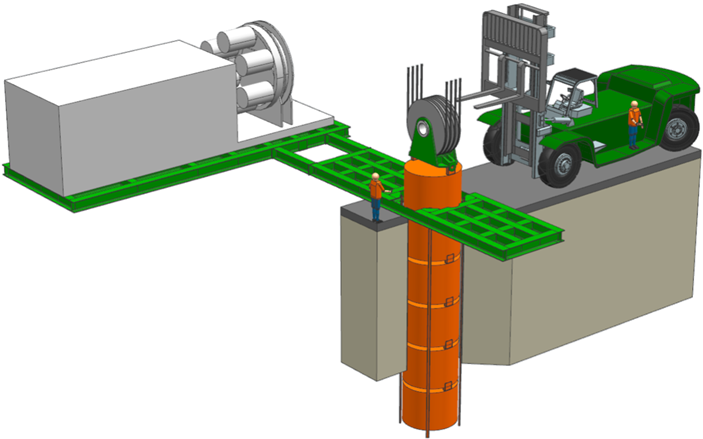

Renewable energy and developing technologies are at the heart of what Frewer Engineering develops with our customers. We have recently been working with Gravitricity to help develop their energy storage system, a novel solution which looks to develop the cheapest levelized cost of energy storage for grid levelling and industry. Frewer Engineering conducted initial design and analysis work to develop the build sequence and weight system concept, a complex endeavour considering the scale of the equipment.

Rotating Machinery – New Software Tool Developed

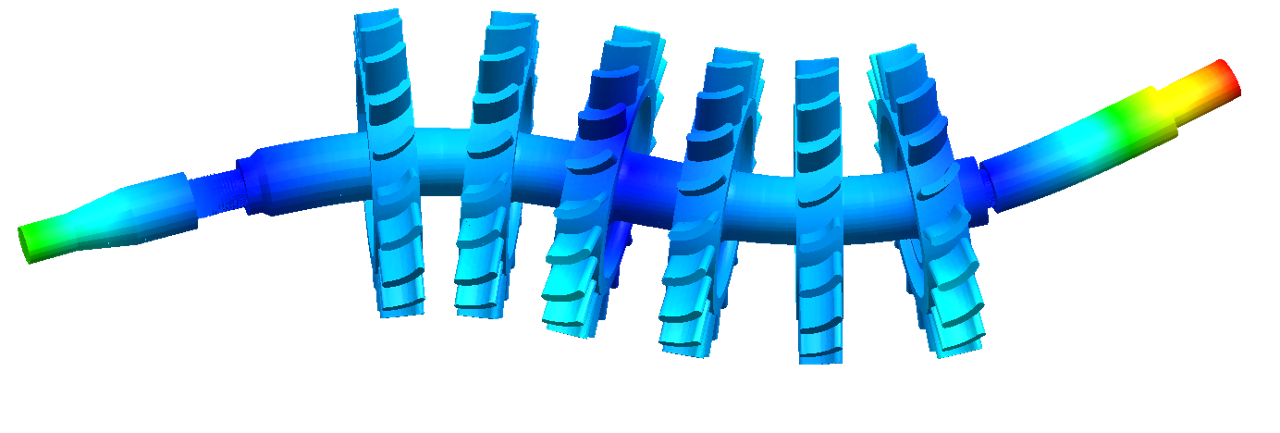

Being a highly sought after area of rotordynamic expertise, Frewer Engineering has recently been investing in new rotordynamics capabilities to improve the efficiency of our analyses. Frewer Engineering has developed a new bespoke software tool that interfaces with MSC Nastran to enable rapid, automated model building and analysis. This tool ensures that we can provide the solution that the customer needs, in the time they need it, offering fast turn-around on rotordynamics analysis. Frewer Engineering’s rotordynamic capabilities include:

- Undamped critical speed maps

- Campbell diagrams and critical speed identification

- Rotor mode shapes

- Forced response analysis

- Torsional response maps

This new software tool has been verified for output against other methods and is now proven to work in practice!

Metal / Composite Structures Update

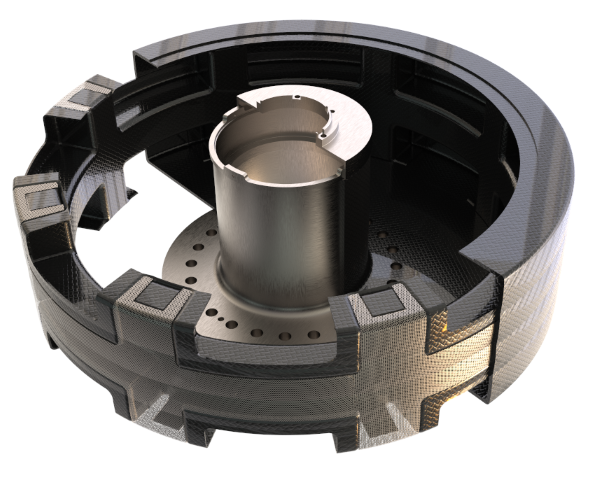

Our composite structures team are currently evaluating new analysis software tools (incl. MSC APEX) to allow faster optimisation of components to reduce weight and optimise stiffness and strength. Our team have also developed unique methods of utilising metallic componentry in the composite manufacturing mould tools, allowing a reduction in tooling costs along with increased structural integrity of the component. The image above showcases this methodology, whereby a metallic structure is used as the carbon composite tool as well as a bearing surface for the completed part, providing the right material for the right job in service. In this instance, bearings work better and provide a longer life when running against high strength metallic alloys whilst the rest of the component utilises lightweight carbon composite to achieve a low inertia for the rotating component, allowing for a complex control system loop in the electric propulsion market.

Advanced Gas Turbine Propulsion Development

Our gas turbine development and test design team are busy on a variety of projects:

- Design of a complete test facility and test rig to develop future compressor and turbine technology to meet environmental gains in performance.

- Design of complex test equipment to understand future science in the field of thermal analysis.

- Design of complex pressure vessels subject to thermal loads.

These large and complex projects require the support of our Thermal Analysis & CFD teams along with our expertise in concepting inlets, exhausts and internal aerodynamic air presentation features.

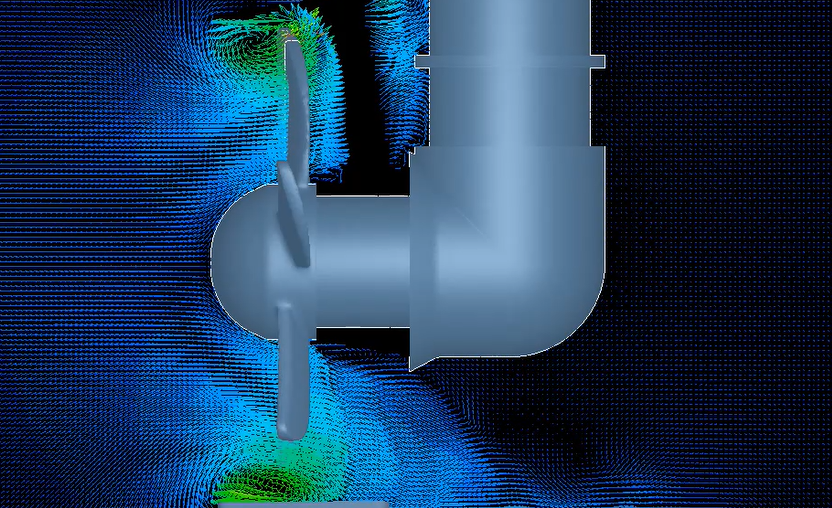

Computational Fluid Dynamics (CFD) & Fluid Structure Interaction (FSI) Analysis

Having both FSI and CFD under one roof allows us to tackle complex analysis problems. Our ability to assess fluid excitation of structures and perform subsequent modelling to eliminate vibration and thus increase the life of componentry gives our clients a rare supporting capability. Our advanced analysis team have many years of experience in the nuclear and defence industry so please do get in touch if this is of interest!

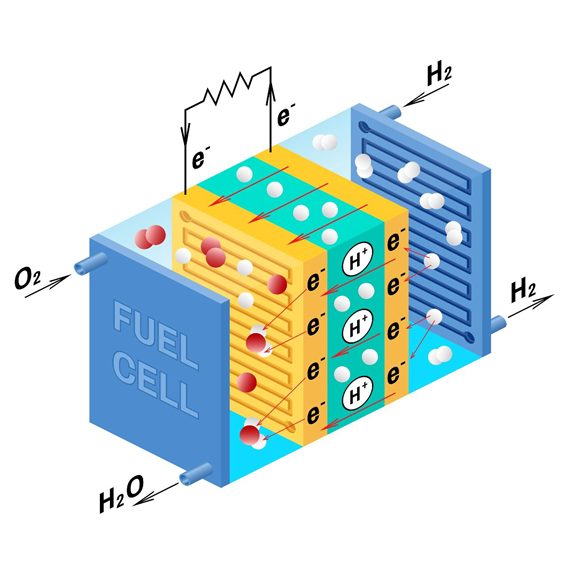

Future Fuel Cell Development & Test – Digital Twins!

Digital Twin Modelling continues to grow as our customers demand greater accuracy of performance when they come to test new products. Our engineering team are working on the modelling of complete process systems for the trial of new Fuel Cell installations which are being developed by one of our customers. The modelling which uses codes such as Python, simulates all elements of what is a complex system to feed and control the fuel cell stacks. Using their understanding of fluids, heat transfer and performance our team are building a digit twin model of the first build and test of the concept.

If you need complex Fluid Dynamics along with Thermodynamic analysis, then please click on the link below to read more:

Inspiring the Next Generation of Engineers

Frewer Engineering are continuing to educate and encourage the younger generation to get involved in engineering! In the past month two of our engineers, Daniel and Kristian, conducted another STEM event at a local school. The team introduced the children to the different types of engineering, before teaching them about forces, engaging them in a water bottle rocket competition and finishing with the launch of our Frewer Engineering model rocket, which the pupils thoroughly enjoyed. Our team at Frewer are committed to promoting the profession to inspire the next generation of engineers!

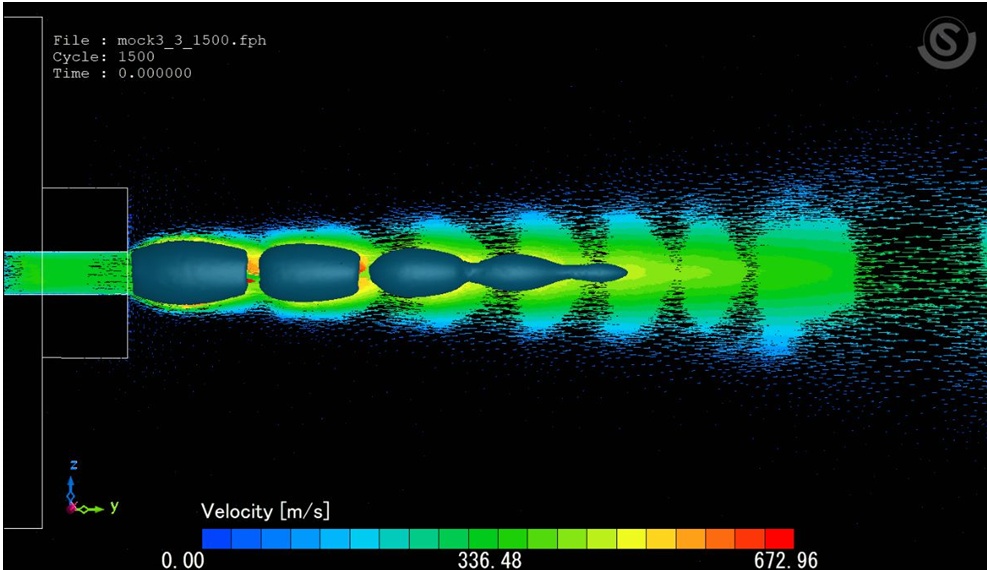

CFD & Marine Defence

Our CFD and FSI team are busy on a number of complex analysis problems to solve drag and noise reduction for defence applications.

Recent investments in security, both physical and personnel means we are better placed to resource this complex and busy market. All three of our divisions, Advanced Engineering, CFD & Thermal and Composite structures remain busy on future equipment development. Our digital security team are now working on our reapproval for Cyber Essentials Plus along with recently completing our registration on the JOSCAR framework allowing procurement departments across the defence industry to access all our company data. This saves our clients money in the form of reduced procurement labour time to set our business up as a supplier on their systems.

Shock & Vibration Analysis

At Frewer Engineering, our engineers are well-versed in the assessment of structures subjected to dynamic loading, including shock and vibration. Our experienced staff can use a breadth of analytical techniques, from the use of relatively straightforward pseudo-static equivalent shock loads, up to explicit dynamic analysis of applied shock pulses and the use of fully coupled fluid structure interaction (FSI) analysis where both the propagation of the shock wave and its interaction with a loaded structure are modelled.

Our experience in vibration analysis includes the use of full transient dynamic FEA as well as response spectrum and random response techniques. Such methods have been employed across a range of industries, including naval, nuclear and aerospace. Our understanding and experience across the range of analytical methods allows us to select the most appropriate solution to our clients’ problems and to perform effective yet efficient analyses as required.

Continued investment in capabilities & equipment

We continue to invest in computing power & speed!

Our state of the art IT infrastructure is now installed and being put to the test with challenging computer modelling in both CFD and complex FEA analysis problems. Having only moved into our current offices around 18 months ago, we are already nearing our limit of capacity – we hope to report in early 2023 of expansion into some neighbouring office units which will add to our current facility. We have just invested in 3D CAD tools in support of our existing SIEMENS NX and PTC Creo tools, adding new licences of SolidEdge to our arsenal, increasing our capacity for CAD modelling and manufacturing drawing production to meet current demand. We can also report that we are currently progressing with our re-audit for Cyber Essentials Plus which is essential to our defence activities.