Latest News June 2020

Frewer Engineering’s Moving Up a Gear

We have been busy developing our services over the last few months – a result of large investments in staff, computing power and IT. We hope you enjoy catching up with our latest news for June 2020, detailing what we are doing to increase our scope of service to our customers!

New “Nuclear Industry” Website Page

Marine Defence

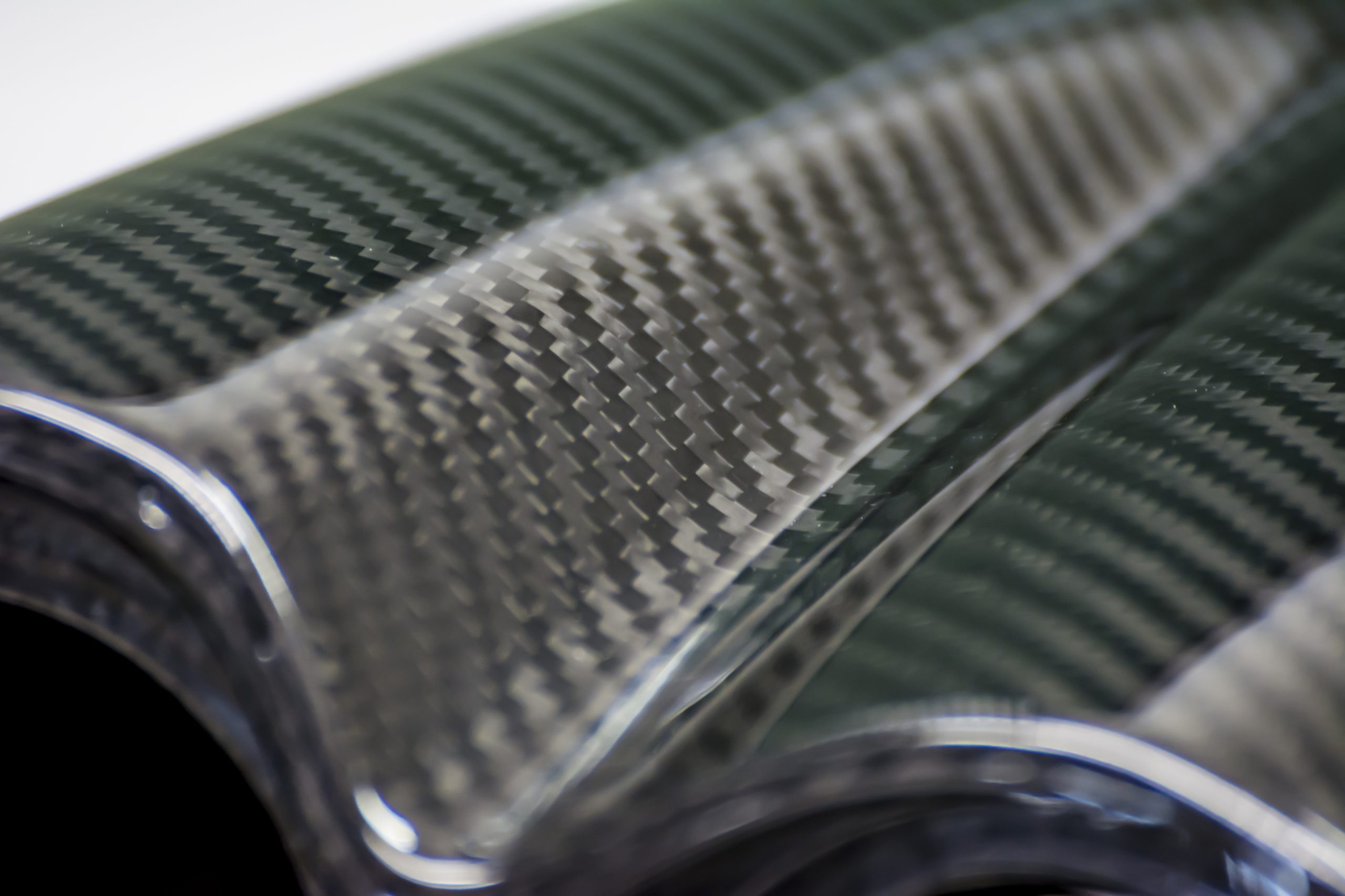

Further activity is underway in the field of submerged marine defence equipment involving carbon and glass fibre composite structures mixed with marine grade high strength metal alloys (co-bonded). Our team are trialling new software tools for composite structure weight optimisation (digimat), which is critical to our clients in order to improve vessel performance. Further we are adopting our new investment in finite element analysis software, MSC Apex, to assist with composite modelling and optimisation as well as much more.

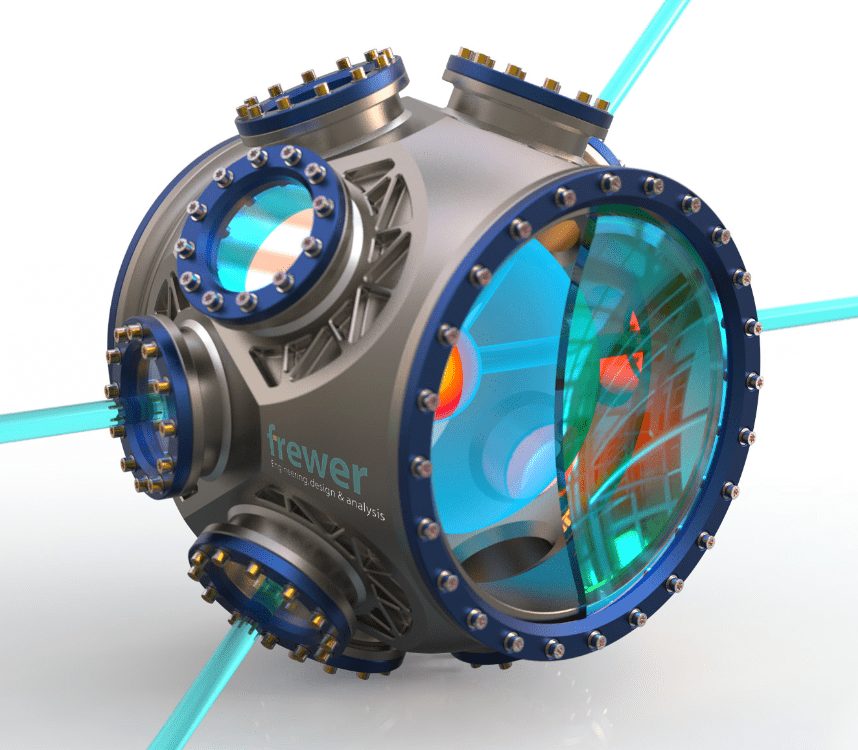

CFD & Advanced Analysis Division Update

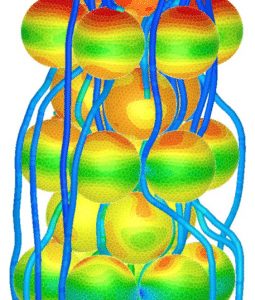

The CFD team have been hard at work upgrading our methods to directly map results from our thermal and CFD analyses to our structural analysis codes. This will streamline our analysis further, for example by allowing us to run thermal analysis on various design iterations and then more quickly evaluate the effect upon thermal stress in the material. Methods like this allow us to more quickly evaluate and optimise designs.

In addition to our constant efforts to develop our capability and methods, we also continue to work on some very interesting problems for our customers.

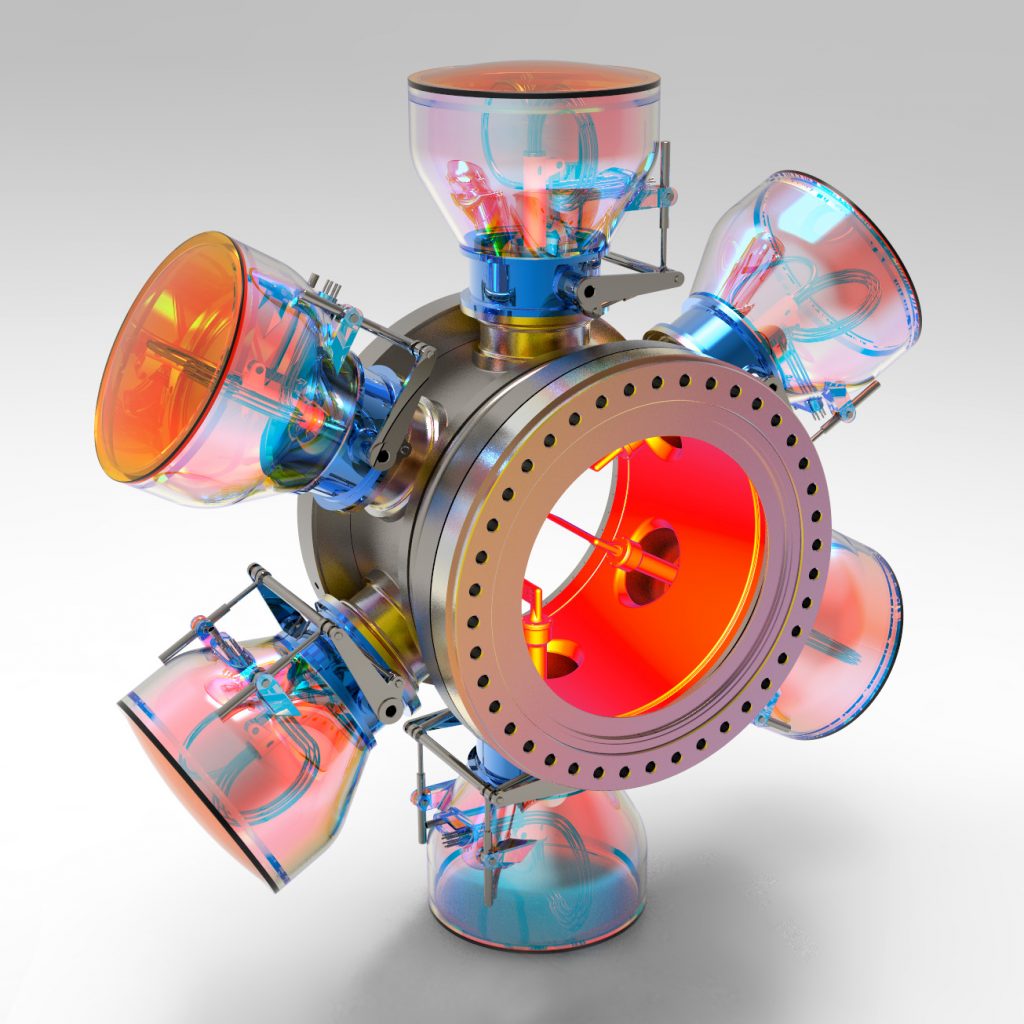

Advanced Engineering Division Update

This involves the use of coupled design and analysis between our CFD team and the Advanced Engineering team to fully model the performance of the equipment before being built. This captures all the hot fluid flow effects along with the interaction on the structures and hence the end result of pressure stresses combined with thermal effects. This takes the risk out of equipment failure on test for our clients.

Our team is also busy working on future silicone chip making equipment for a USA based client (California). This involves modelling of vibrational effects on a very complex mechanical assembly, along with the modelling of shock loading to simulate transport and accidental handling. This addresses the risk our client has of damage during transportation of the equipment to their site in California.

Advanced Composites Division Update

The team is also performing design optimisation and analysis of mutli-material co-bonded structures for submarine use. Again, optimising weight versus performance is key along with modelling the effects of shock loading and much more.