Latest News December 2020

Welcome to Frewer Engineering’s Latest News December 2020.

As we come to the end of what has been an interesting and challenging year for all, take a look at our plans for 2021 as well as an update on our new and on-going projects.

We hope you enjoy the read.

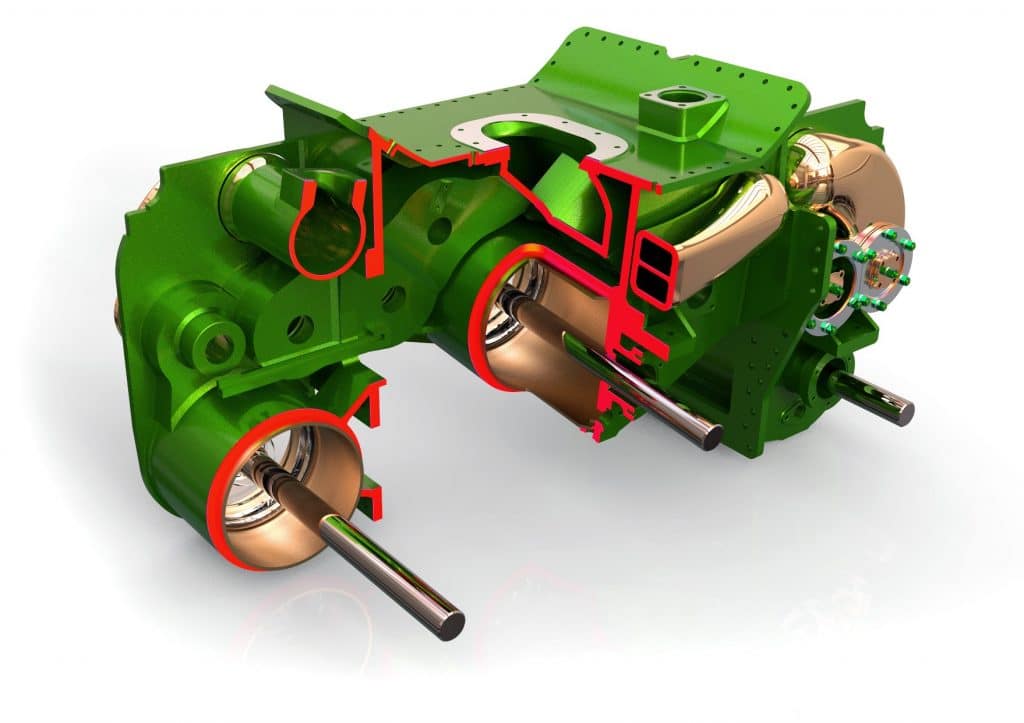

CFD & Advanced Analysis

Frewers have won a key initial contract in support of the heritage new build of Sir Nigel Gresley’s P2 ‘Mikado’ – 2007 Prince of Wales. Our initial involvement centres on the flow optimisation of the Cylinder Block, which has been upgraded from cast material to a plate steel fabrication.

The cylinders will run at a higher pressure than the original, with larger bore supply pipes and modern materials – this may just be the most powerful version of the UK’s most powerful passenger steam locomotive.

Built for traction more than top speed, the P2 is expected to haul in excess of 600 tonnes, for steam rail-tours through the steep railways of Scotland, as originally intended by Gresley. Frewer Engineering are proud to be supporting this latest endeavour by the A1 Steam Locomotive Trust – https://www.p2steam.com/

Gas Turbine Test Equipment

Based on our analysis, our collaborating manufacturers are now set to purchase the necessary forgings, while we finalise the design. Working in this concurrent way ensures that collectively we can deliver the final test rig to the end customer allowing their testing to commence on schedule.

Earlier in the year we successfully passed the critical design review of an aero-engine slave pylon to enable ground testing of the same engine platform mentioned above. Initial cutting of metal is now complete and fabrication of the main hardback structures is well underway at facilities in the North West of England.

Marine Defence

Advanced Composites

The team are also developing their qualification planning capabilities for aerospace composite structures. Some of the teams designs are now in manufacture with two organisations and ensuring “design for manufacture” is achieved is critical to ensure a reliable manufacturing process along with a working product for the end customer.

Business Update

We are continuing to provide full turn-key engineering solutions within and across our newly created divisions. For further information on these divisions follow the links below:

Advanced Engineering Division

Advanced Composites Division

Advanced Analysis Division