Latest News July 2025

Welcome to the latest Frewer Engineering newsletter.

This month’s edition features our new placement students, rapid response capabilities, test facility & gas turbine expertise, and CFD support for the University of Bath.

We hope you enjoy the read!

Welcoming our New Placement Students

We are delighted to welcome Anthonie (left) and Alessandro (right)!

Anthonie recently finished his 3rd year studying Aerospace Engineering at the University of Nottingham, he has a strong interest in composites, numerical methods, and data analysis. He has worked on many projects including the design of an ultra long-range aircraft and composites research. We’re excited to have Anthonie on board and look forward to his future contributions.

Alessandro joins us from the University of Bath, where he has just finished his 2nd year studying Aerospace Engineering. He has contributed to a range of technically ambitious projects from mechanical launchers and pneumatic actuators to control systems and EV battery module assembly lines. Additionally, Alessandro has a strong grounding in mechanical design, controls, and CAD, making him a great addition to the team.

We look forward to the year ahead and will keep you updated with their progress!

Frewer’s Rapid Response – Quick ramp up to support your project needs

At Frewer Engineering, our small-business structure enables direct, agile communication with clients, no layers or delays. Projects proceed with fewer handoffs, direct communication, and swift iteration, from early phase work like concepting and requirements capture, to final design and handover.

We’re proudly building on our track record of delivering rapid, high-quality engineering solutions across all industries. This capability is underpinned by our specialist engineers, each bringing vast depths of expertise to every project we undertake.

From CAD-driven structural optimization to coupled FEA/CFD workflows and bespoke tooling design, our integrated approach ensures we can create and validate high-performance engineering solutions for your individual needs.

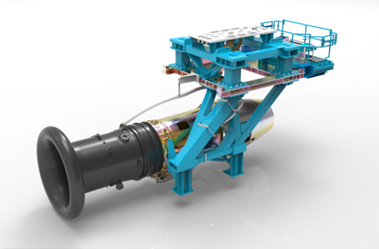

Test Facility Upgrades

As testing demands grow within industry across all engineering sectors, many facilities are under increasing pressure to modernise aging infrastructure and expand capability. Whether it’s traditional aerospace test rigs or more specific test systems, upgrades are often essential to maintain precision, safety, and efficiency.

Frewer Engineering offers specialised support to help update test equipment and enhance facility functionality through advanced engineering packages. With expertise in mechanical, structural, and fluid systems design and analysis, we can deliver bespoke solutions that extend facility life or expand operational capacity.

Our deep understanding of dynamic loading, fatigue life, and thermal management allows us to improve hardware and test outcomes. Upgrade solutions can be delivered efficiently, meet modern standards, and align with evolving R&D and validation needs.

As the need for more capable, future-ready test environments grows, Frewer continues to deliver innovative, efficient, and reliable solutions to keep our clients’ development moving forward.

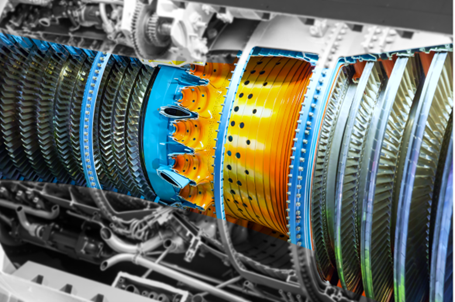

From Intake to Exhaust – Frewer Delivers

Frewer Engineering’s roots lie in gas turbine design and development, delivering end-to-end capability, from composite intakes to high-temperature exhaust systems.

Our experience spans decades of collaboration with major OEMs and test facilities, supporting both prototype and in-service systems. Frewer’s capabilities extend across concept design, containment systems, thermal management, and bespoke structural components, each tailored to the specific demands of aero engines, power generation, or high-integrity test environments.

Whether it’s a rotating rig, combustion test section, or closed-loop air flow systems, Frewer integrates design and analysis to streamline delivery and certify performance at every stage.

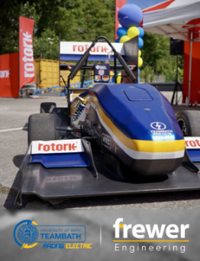

University of Bath Consultancy Support in CFD

Frewer Engineering is delighted to continue our partnership with the University of Bath’s Formula Student team—Team Bath Racing Electric—as a Silver Sponsor for another year. Supporting the next generation of engineers remains a priority for us, and we’re proud to contribute technical expertise to help the team push the boundaries of performance.

Our involvement has focused on the development of CFD and thermal models, which play a critical role in the aerodynamics and cooling systems of the 2025 car. Our analysis delivers practical insights that complement the team’s own innovation and ambition.

We extend our congratulations to Team Bath Racing Electric on their continued success this season, including being the fastest EV across a one lap sprint at the Formula Student UK competition at Silverstone. It’s been a pleasure working with such a dedicated group of students and we look forward to another exciting year of collaboration.