Latest News September 2025

Welcome to the latest Frewer Engineering newsletter.

This month’s edition features Frewer’s presence in Toulouse, advances in realistic composite fatigue modelling, and a successful PDR.

We hope you enjoy the read!

Frewer Engineering at the Toulouse Aerospace Testing International Expo

This September, our Lead Engineer Kristian Mahon attended the Aerospace Testing International’s Test and Development Show in Toulouse. The event brings together engineers, researchers, and organisations at the forefront of aerospace testing, providing opportunities to share ideas and explore sector developments.

Kristian met with industry colleagues to discuss current challenges and opportunities in testing and development, helping us better understand the needs of the aerospace community and where Frewer Engineering’s skills can add value.

For more information on how we support the aerospace sector with testing requirements, please explore our website.

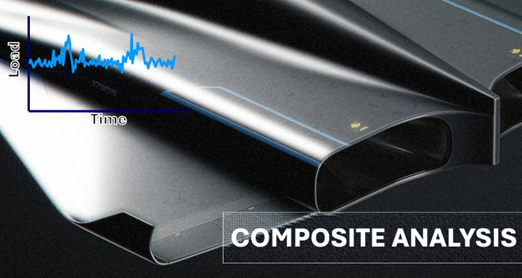

Composite Fatigue: Developing Realistic Load Profiles from Flight Data

Composite fatigue is a critical challenge in UAV design, where lightweight structures often operate close to material limits. Traditional fatigue assessments use simplified load cases that rarely match real-world conditions.

By extracting load spectra from flight telemetry (accelerometers, mission logs, or onboard strain data) we help create realistic inputs for finite element models and test campaigns. This enables accurate prediction of crack growth and damage progression, reducing structural conservatism, cutting redesign costs, and extending service life.

The result is safer, lighter, and more competitive airframes for both commercial and defence applications. Please contact us if this service could support your UAV platform.

Building Confidence in Complex Systems: PDR Success

A successful Preliminary Design Review (PDR) is a pivotal step in any gas turbine development programme, setting the course for downstream design and validation.

Recently, Frewer Engineering supported a client in this sector, providing additional work on supporting systems and ancillary mechanisms that play a vital role in enabling overall engine performance. By applying our expertise, we helped ensure that critical components were ready for review under tight programme timelines.

Our engineers worked seamlessly within the client’s structure, adopting their processes and decision-making cadence to deliver efficient, integrated support. This approach meant potential risks were resolved quickly, documentation was delivered to a high standard, and the PDR concluded with confidence in the path ahead.

For organisations developing advanced aerospace technologies, Frewer Engineering provides the flexible expertise needed to de-risk early design phases and keep complex programmes on track. Click below to learn more about our capabilities.