Latest News October 2025

Welcome to the latest Frewer Engineering newsletter.

This month’s edition features our presence at Advanced Engineering, legacy composites upgrades and analysis of high-speed machinery.

We hope you enjoy the read!

Frewer Engineering at Advanced Engineering 2025

Frewer Engineering was proud to exhibit at Advanced Engineering 2025 within the Make UK Defence Pavilion, showcasing our broad range of design and analysis capabilities spanning aeronautical, space, marine, defence, and energy sectors.

The event provided an excellent opportunity to connect with both long-standing customers and new industry contacts, reinforcing existing partnerships and exploring potential collaborations. Our team valued the chance to engage directly with the wider engineering community, exchanging insights on emerging market trends, innovation, and developing technologies shaping the future of advanced manufacturing and engineering design.

We extend our thanks to everyone who visited our stand. It was great to share how our collaborative, high-performance engineering continues to deliver cutting-edge solutions across complex and safety-critical sectors.

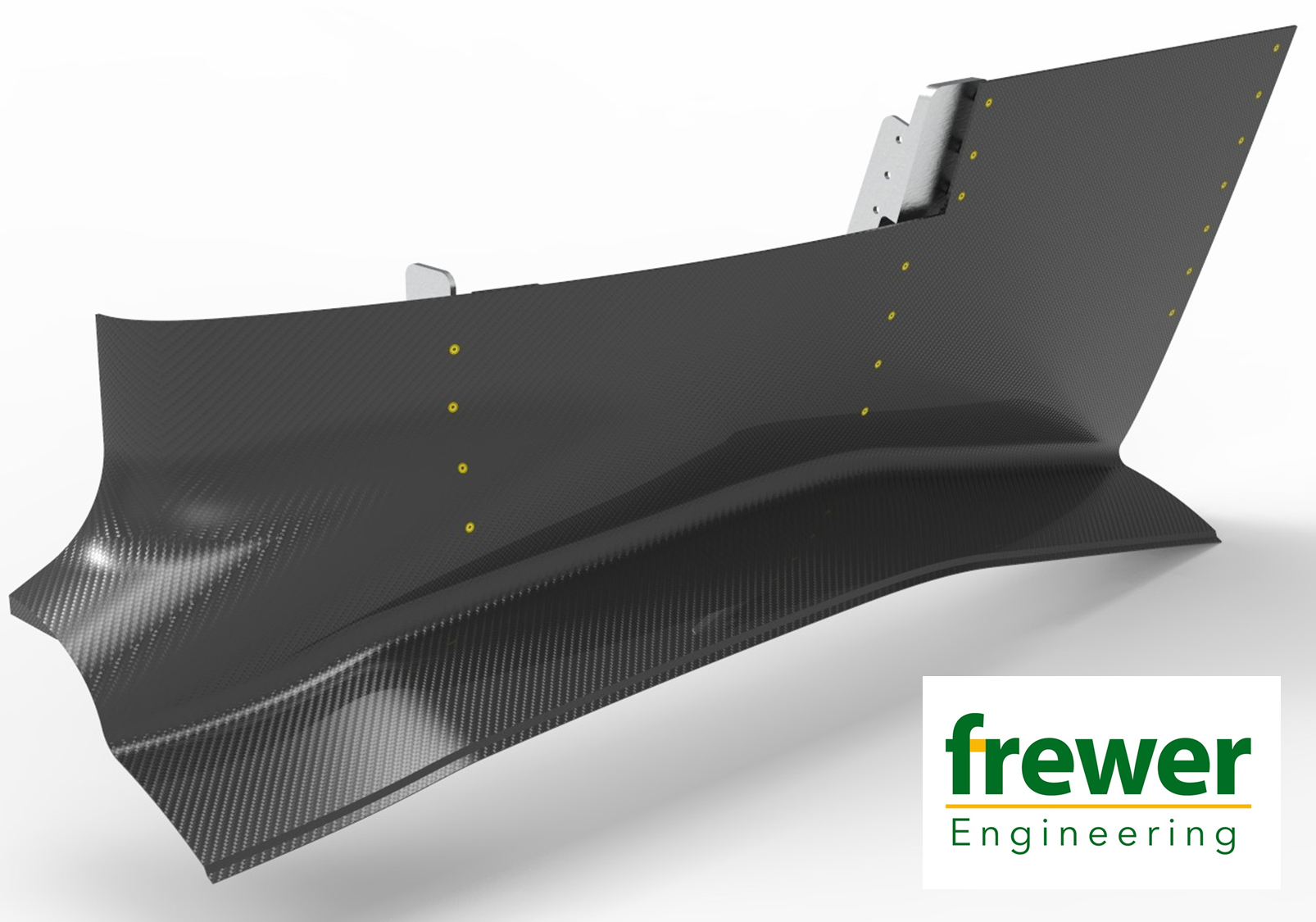

Legacy Composite Structure Upgraded for Improved Maintainability

Frewer Engineering recently supported a long-standing customer with a modification to a previously designed composite aerosurface, introducing larger maintenance access panels to enhance serviceability.

Our engineering team undertook a full redesign and structural re-analysis of the affected apertures, ensuring that the integrity and performance of the component were fully maintained. The work included comprehensive re-substantiation of the design to meet stringent certification and manufacturing requirements.

This project highlights our ability to revisit and evolve legacy designs, applying our deep understanding of composite structures to deliver practical, compliant solutions that extend the service life and maintainability of critical aerospace hardware.

Please visit our website for further information on how we can support technical requirements relating to composite structures.

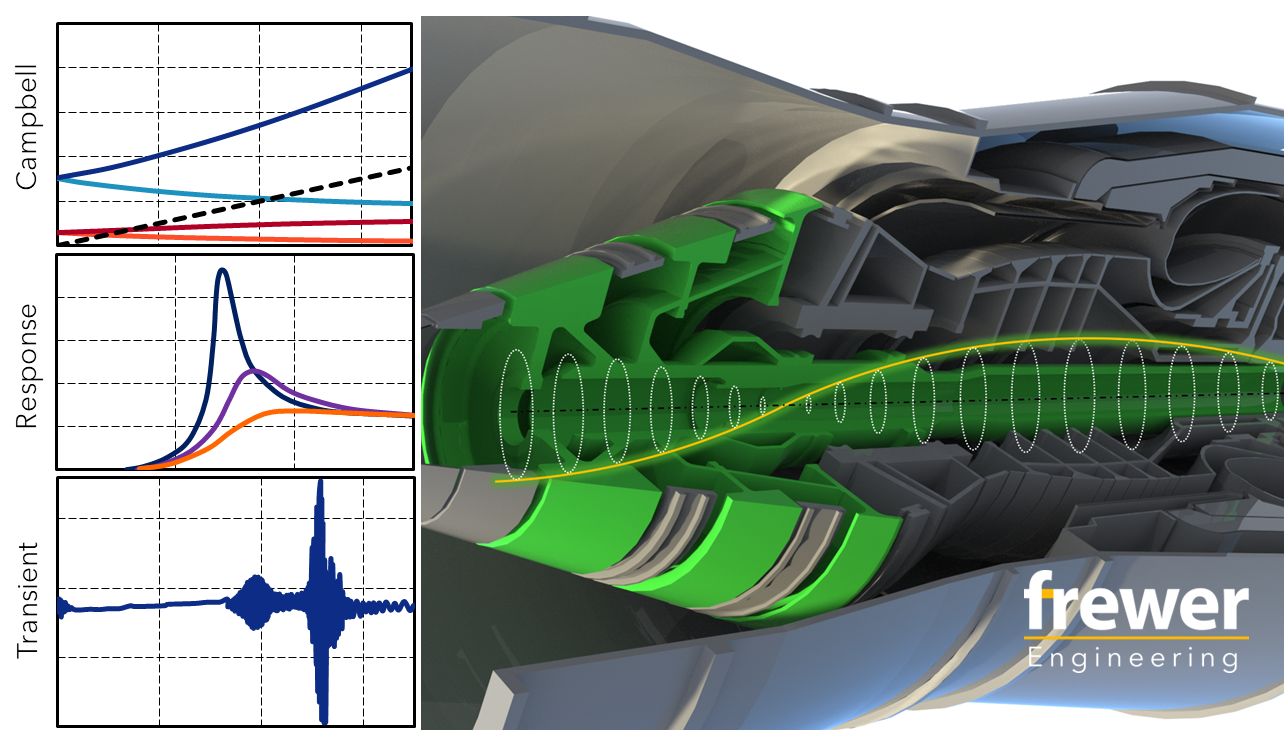

Engineering Confidence in High-Speed Machinery

At Frewer Engineering, our rotordynamics capability plays a vital role in supporting the design and analysis of high-speed rotating machinery across aerospace and industrial sectors. Whether it’s turbines, compressors, or advanced propulsion systems, understanding rotor behaviour is essential to ensuring safe, reliable, and high-performance operation.

Our team provides in-depth rotordynamic analysis, including critical speed mapping, modal analysis, and unbalance response studies. These techniques allow us to predict and mitigate vibration issues that can lead to fatigue, performance loss, or failure.

By using advanced simulation tools, we analyse rotor systems across a range of operating conditions, accounting for both thermal and structural influences. This holistic approach ensures our clients receive accurate insights that inform better design decisions and reduce development risk.