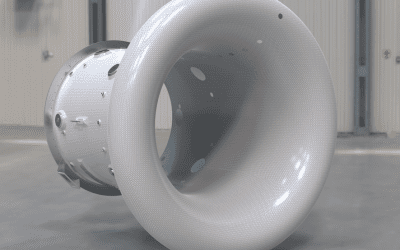

This case study follows how Frewer Engineering’s customer required an “Airmeter” air intake to accurately control and monitor air flow into their engines, allowing them to optimise their latest gas turbine engine designs.

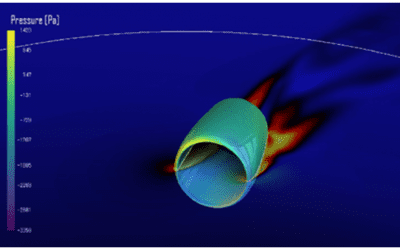

Fluid-Loaded Structural Analysis

The case study follows Frewer Engineering’s look into combined computational fluid dynamics (CFD) & finite element (FE) stress analysis for structures under complex fluid loading conditions such as wind & wave loads.

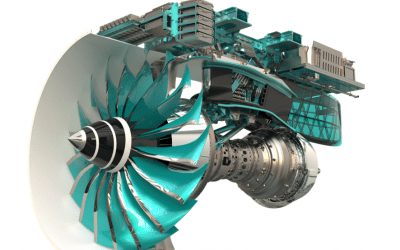

Gas Turbine Ground Testing Pylon

The case study follows how Frewer Engineering mobilised our multi-disciplinary team to deliver a new pylon design that could demonstrate cleaner, more efficient flight as our customer’s engine sizes continue to increase.

High-Temperature Test Equipment

This case study demonstrates how Frewer Engineering provides design & analysis for high-temperature & pressure test equipment. This includes pipework, custom vessels & complex geometries such as combustors or internal air systems.

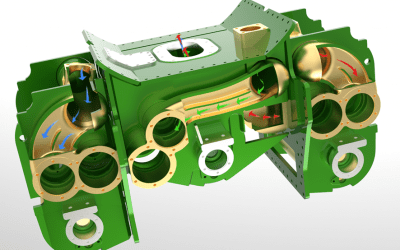

A1 Steam Cylinder Block Optimisation

For this case study, Frewer Engineering were approached by a team of enthusiast who are making the design of the world’s most powerful steam train a reality.

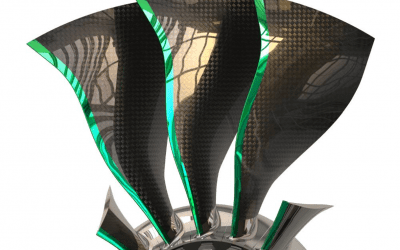

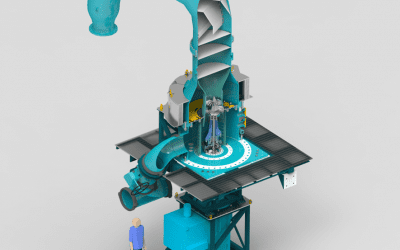

Blade Testing Rigs

This case study outlines how Frewer Engineering’s proven capability in structural analysis, rotordynamics, and integrated design for high-speed machinery enables the development of cutting-edge blade testing rigs for fan, compressor and turbine testing.

Single Arm Blade Test Unit

In this case study, our customer required the development of a new single arm blade test unit to test performance under overspeed and bird strike conditions.

Hydrogen Fuel Cell Test Cell Design

This case study follows how Frewer Engineering supported the design and development of a new suite of SOFC/SOEC test facilities including digital twin modelling, pipework system design, component specification, thermal structural analysis and assessment to relevant codes.

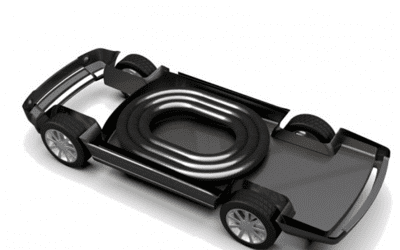

Composite Hydrogen Pressure Vessel

For this case study, Frewer Engineering completed R&D of composite wound hydrogen fuel tanks. Specifically, the feasibility of integrating these into to existing EV modules. Exploring novel shapes, optimising mass fraction, and reviewing structural challenges.

Renewable Energy Capability Study

This case study outlines how Frewer Engineering applied engineering first principals in a technologically agnostic manner, to evaluate options for renewable energy generation at the production sites of a large industrial customer.

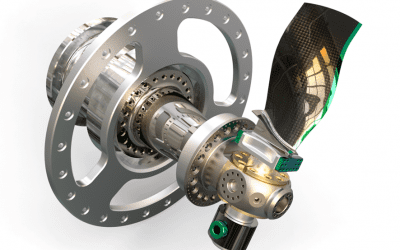

Whittle Laboratory NCPP Rotating Rig

This case study follows the new NCPP rotating rig, a multi-purpose, high-speed rig, capable of rapidly testing single gas turbine engine stages.

Submarine Mast Raising Equipment

This case study covers Frewer Engineering’s design of composite telescopic submarine mast assembly components, using state-of-the-art materials and manufacturing techniques.