Latest News April 2024

Welcome to the Frewer Engineering latest news and updates.

In this edition, we’re excited to share the final submission of our research paper detailing the design and analysis activities completed on the new high-speed rotating rig for the National Centre for Propulsion and Power.

We’re also excited to announce the expansion of the Frewer team, and our attendance at the ASME Turbo Expo in London from June 24th-28th.

Continuing Support to Gas Turbine Development

This June the team will be attending the 2024 ASME Turbo Expo at the ExCel centre in London, where we will be presenting the findings of our research on the development of a high-speed rotating rig. We will also be demonstrating the design and build of the rig with our interactive VR setup. From June 24th – 28th members of the senior management team will be on hand at our stand to meet clients old and new. If you would like to arrange a meeting, please feel free to contact us!

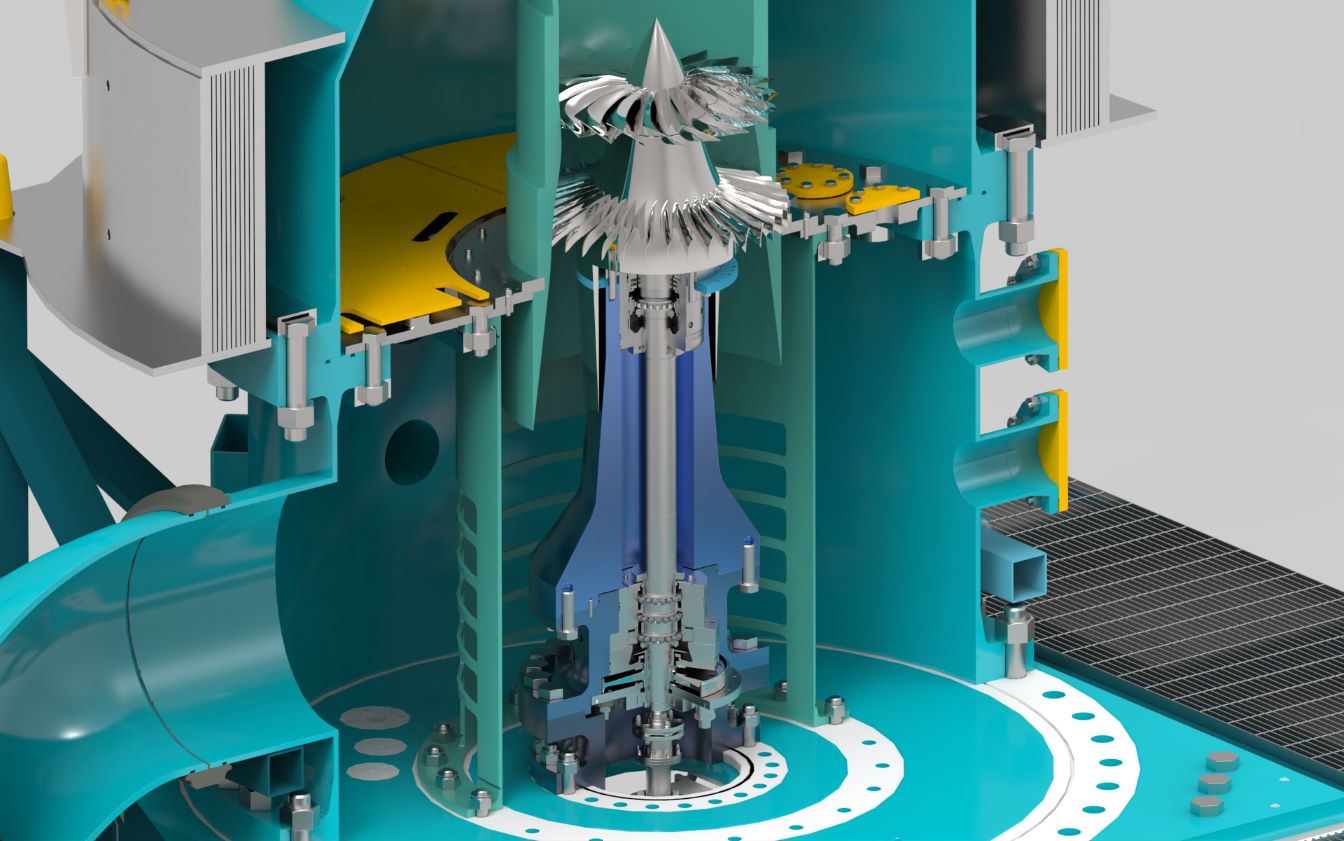

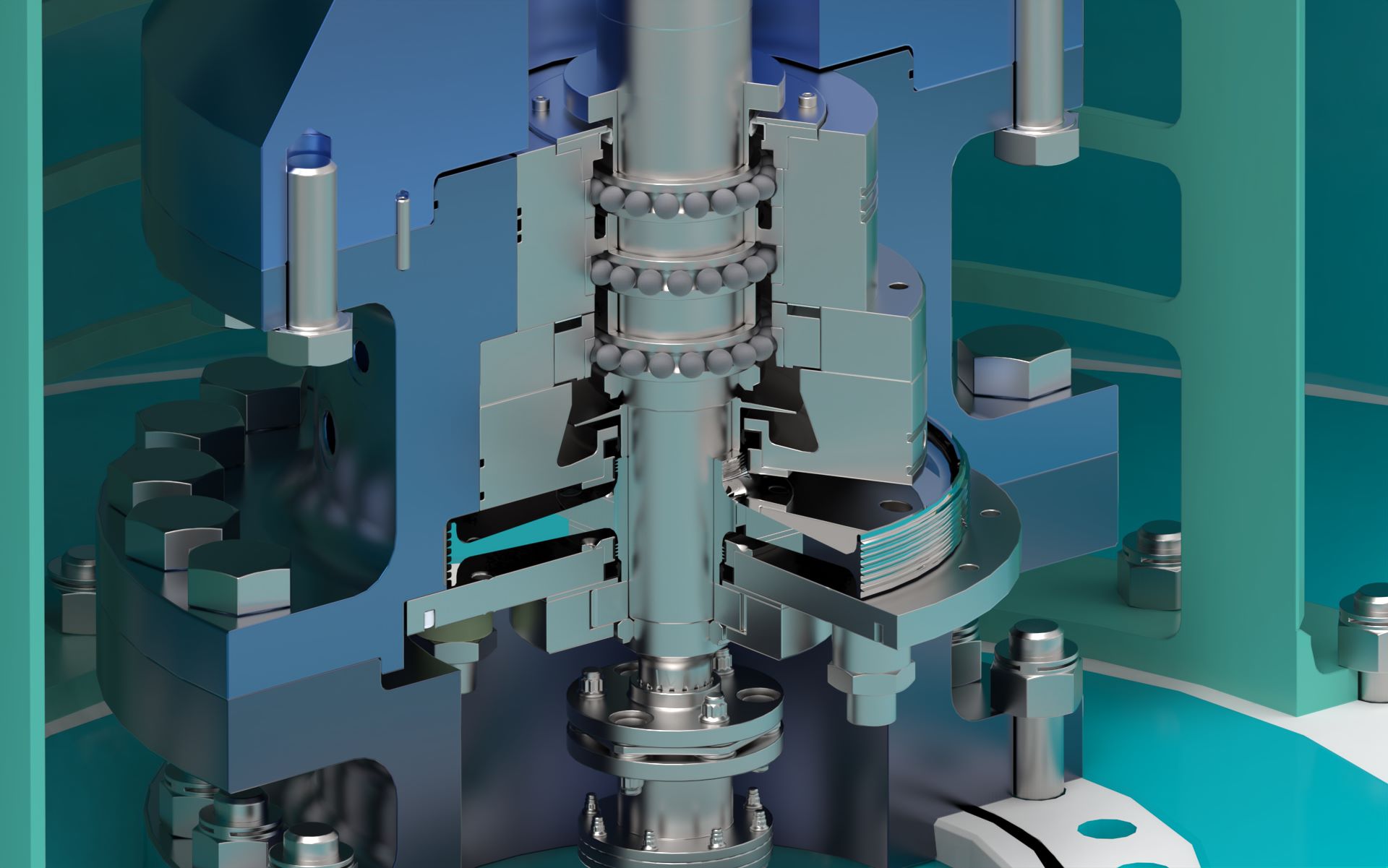

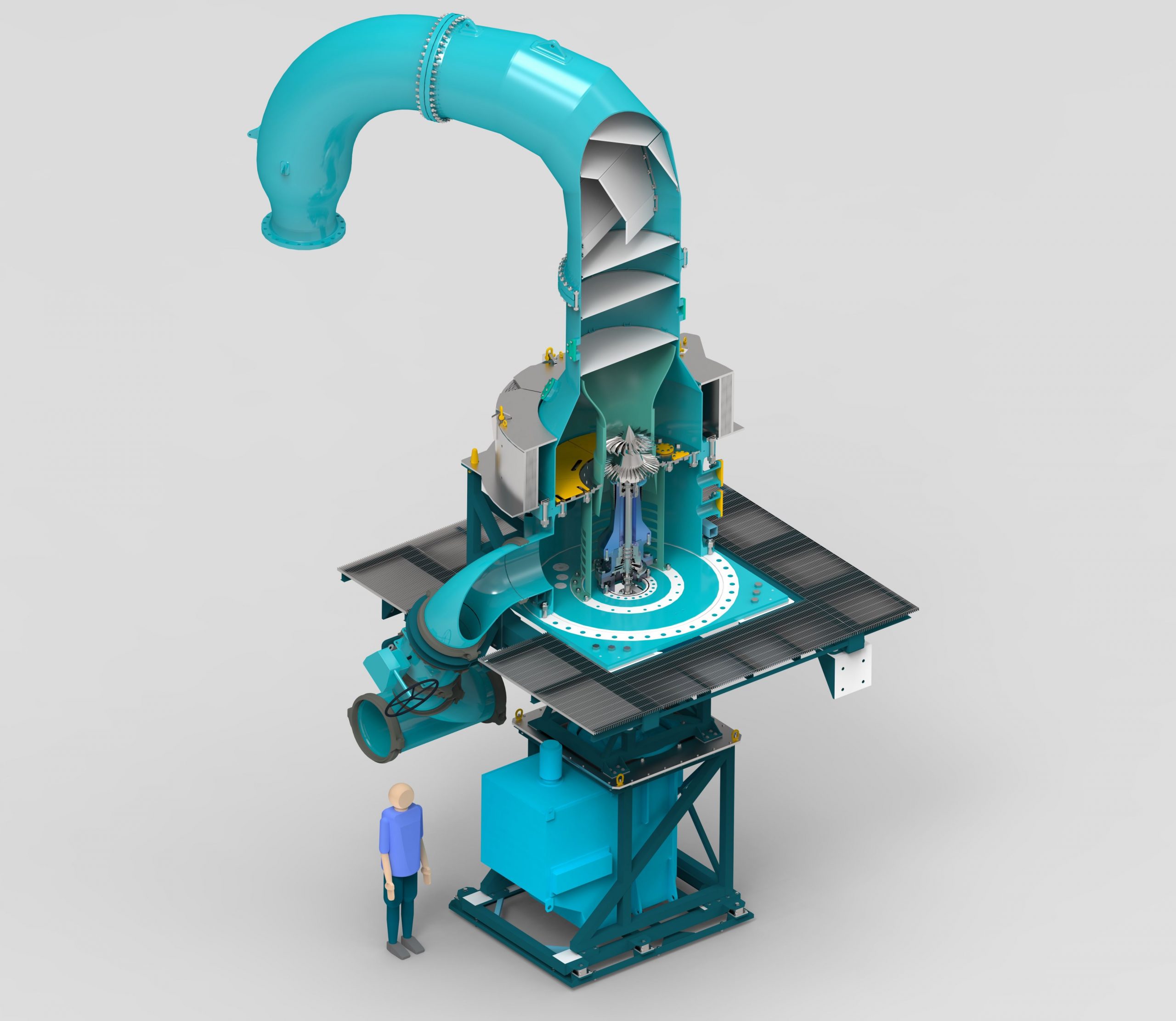

Frewer Engineering has submitted its final version of the research paper regarding the development of the high-speed rotating rig for the National Centre of Propulsion and Power (NCPP), located at the University of Cambridge’s Whittle Laboratory. Our experienced team of engineers took the project from concept to detail, designing and analysing major components including pressure vessel sections, high-speed rotatives, containment solutions, internal flow structures and structural support frames.

The 1.2 MW driveline is engineered to handle various single-stage experiments, whether it involves a high hub-tip ratio compressor, a low hub-tip ratio fan, or a turbine. The flexibility of the rig is the driving factor in its ability to test a range of conditions, from blade relative Mach numbers of 0.5 up to 1.3 and a Reynolds Number based on chord from 80,000 up to 2,000,000. The development of this test rig allows for rapid testing of compressor, turbine and fan single stages within a single test unit, accelerating the rate at which significant research can be performed.

Crafting Solutions: Frewer’s Expertise in Understanding Client Needs

At Frewer, we pride ourselves on our unparalleled ability to grasp and fulfil the diverse requirements of our clients across a spectrum of engineering domains, from gas turbine design and analysis to pressure vessel structural assessments. With extensive expertise in advanced design and analysis, we stand ready to tackle the most intricate challenges presented to us.

Requirements Capture: Clients often approach us with complex and multifaceted problems that they require assistance in categorising. From initial meetings to understand where we can assist, through to developing detailed design and analysis reports, we leverage our expertise to propose effective and tailored solutions. Our role doesn’t just stop at the proposal, we provide continuous compliance assessments against requirements during the project, alongside open communication and regular feedback and review sessions, ensuring our solution aligns with the customer’s vision.

Leading Innovation: Innovation is our driving force. High-profile customers have approached us with complex projects lacking a solution, which could lead to large delays and high costs. To overcome these challenges, we provide leading design and analysis across a broad range of applications by employing our proficiency in CAD, CFD and FEA. Using these tools and our wealth of retained knowledge, we deliver innovative, data-driven solutions, providing optimised and defensible answers to why a certain choice should be made.

Resourceful Support: In the past clients have come to us after finding they lack resources or a specialist skill set to deliver on their project. In cases such as these, we’ve seamlessly integrated our resources into their team, including dedicating members of our specialist analyst team to help complete the job. In other instances we’ve taken on the whole project completely, putting our expert team to the task of taking an initial concept through to detail. To find out more about our specialisms, click here.

Frewer’s Key Services

- Full turnkey design service

- Requirements capture

- Compliance methodology development

- concept design with preliminary supportnig analysis

- Detail design and technical drawings

- Manufacturing support

Team Bath Racing Electric

Frewer is proud to announce we have recently agreed on a sponsorship deal with Team Bath Racing Electric. A successful electric Formula Student team that competes both nationally and around the world. Formula Student is a challenging engineering competition in which university teams design, build and test a single-seater race car from scratch. The teams face each other in competitions in the UK and abroad to showcase and race their prototypes, proving their engineering excellence.

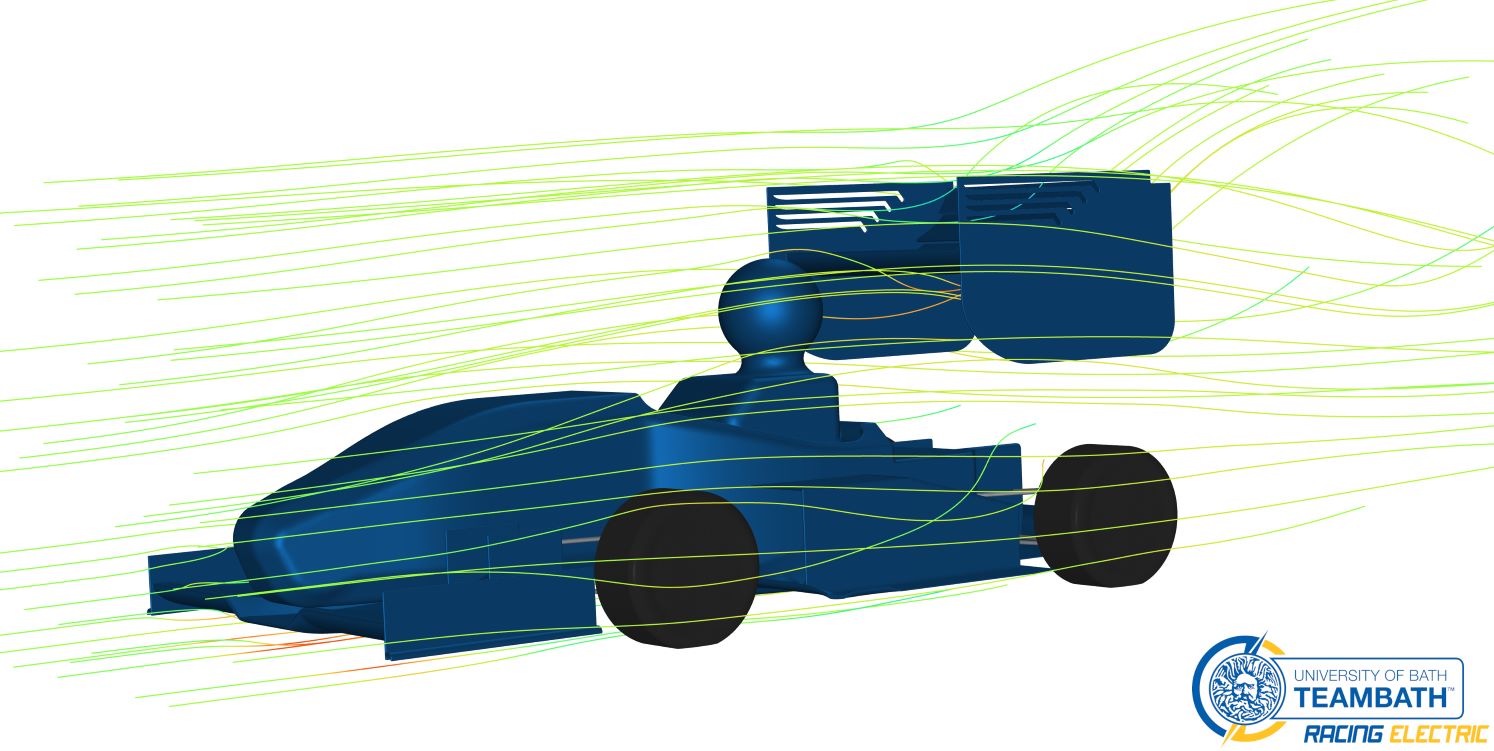

Modelling the car’s aerodynamic features using CFD is challenging and complex, but essential for predicting the flow physics around the car and attaining aerodynamic parameters such as lift and drag coefficients. To overcome these inherent complexities, our proficiency in CFD and thermo-fluids is providing expert advice to help the team make the most of their modelling capabilities. This includes supporting the students with the validation of their existing CFD and providing guidance on how to improve model accuracy and efficiency. In addition to this, we have planned future involvement in the development of heat transfer models where real-world testing would otherwise be expensive and time-consuming.

We are hopeful this deal with prove fruitful for both parties and that the team will continue to grow and be successful. To read more about our analysis capabilities, click here.

New & Familiar Faces: Frewer’s Team is Expanding

Continued expansion at Frewer Engineering welcomes Pedro Sequeira and the return of Geoff Sherwood.

Pedro joins us with an MEng in aerospace engineering from the University of Bristol. Pedro’s final year project involved the design of a fixed-wing aircraft, with a focus on propulsion and performance, integrating a systems approach to meet the set of requirements and optimise fuel consumption. With this experience Pedro will reinforce our innovative design and analysis team, bolstering our service to customers.

Geoff has returned to Frewer Engineering after acquiring valuable experience in the nuclear industry. Geoff has multiple years of experience at Frewer as a design and analysis engineer, having contributed to a range of significant projects, including the Rolls Royce UltraFan© pylon design. Settling into his role as Lead Engineer, he has already demonstrated the value of his fresh expertise on ongoing projects and is providing a safe pair of hands for our customers.