Latest News July 2023

Welcome to the Frewer Engineering latest news July 2023.

This issue reports on our new engineering starters and latest design and analysis projects.

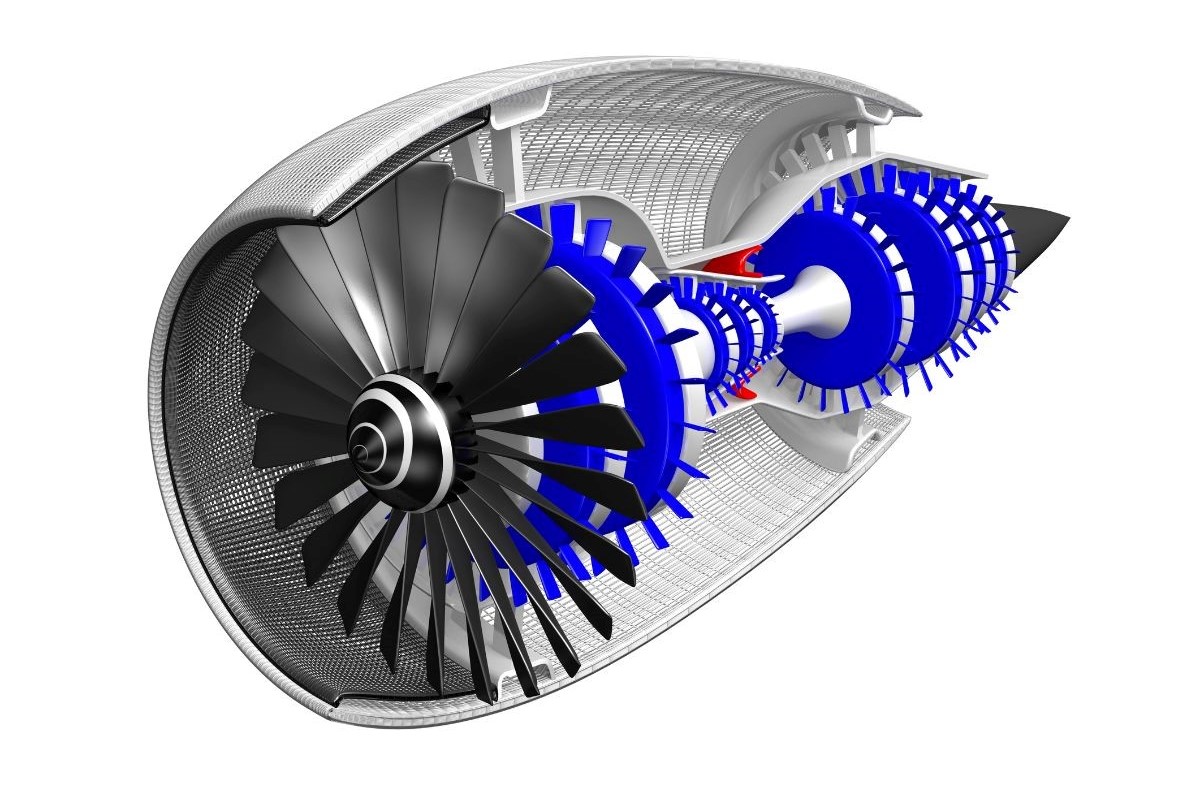

Future Compressor Research & Design

Our future gas turbine test equipment design team are busy on a multi-purpose compressor, turbine & fan test rig design program, which is now approaching the Critical Design Review (CDR) stage.

The test equipment has been designed to allow rapid changes in rotating test articles and associated internal aero profiles, enabling quicker investigation of possible internal aerodynamic improvements.

The aim is to investigate and quantify greater performance gains, which in turn improves fuel efficiency and reduces the environmental impact of future propulsion systems.

This project has involved many of our specialists, including those from the following fields:

- CFD

- Thermal analysis

- Mechanical design

- Rotordynamics

- CAT 4 Pressure equipment design

- Bearing selection and rotor design

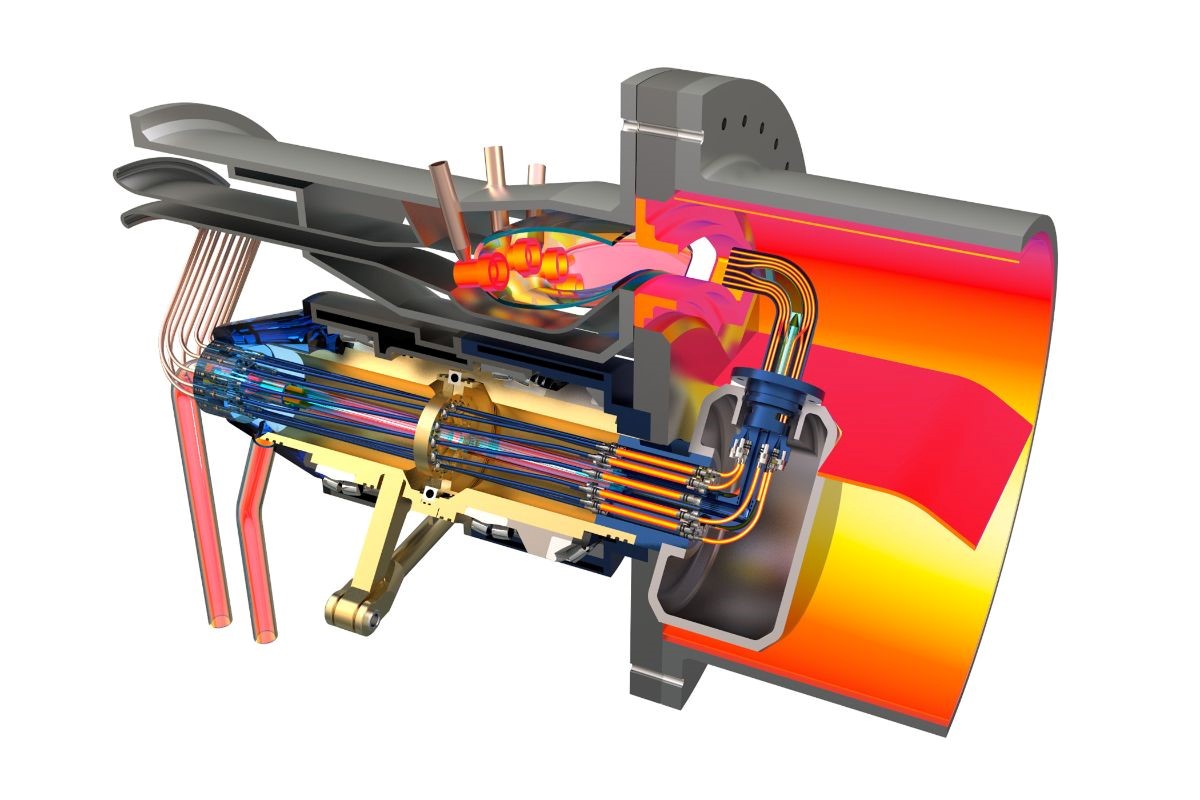

High Temp Combustion Test Equipment Design

Our advanced analysis team have been working on complex very high temperature equipment design. This involves CFD analysis of internal air flows around combustion equipment on test. Our end customer has designed and built the combustor which is then integrated into the test rig to facilitate operation, with the ability to accurately sample the emissions along a swept arc, assessing performance across the entire combustor unit.

A full thermo-mechanical model was required to simulate run up and run down, as well replicating normal operation of the equipment.

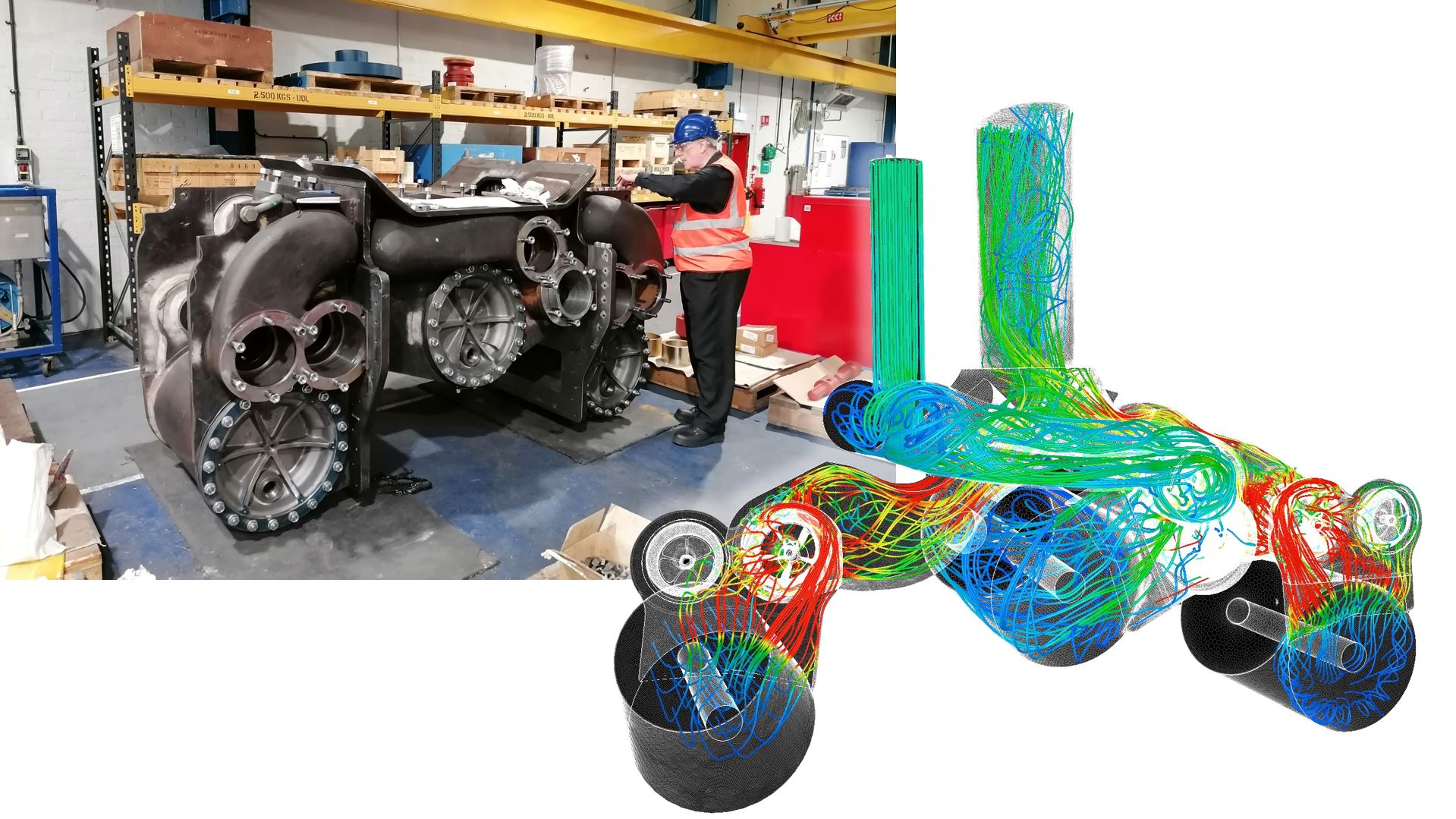

Our CFD Analysis team’s work is in manufacture!

A little while ago, Frewer Engineering were engaged in a body of thermal hydraulics work for a charity in Darlington – the A1 Steam Locomotive Trust. The Steam Trust are working on a modern-day build of a legacy steam engine design from Sir Nigel Gresley.

This is planned to be Britian’s most power passenger steam locomotive, the P2 No. 2007 Prince of Wales. Frewer Engineering carried out detailed Computational Fluid Dynamics (CFD) simulation work, to check for constrictions in a modified design of the Steam Cylinder Monoblock.

The new block is slightly thinner in width but is now a stronger, fabricated design, capable of higher steam pressures than the original casting. We’re happy to report that this design has now been fully realised and committed to steel, at the manufacturers, Howco, in Scotland – a proud day for all parties involved.

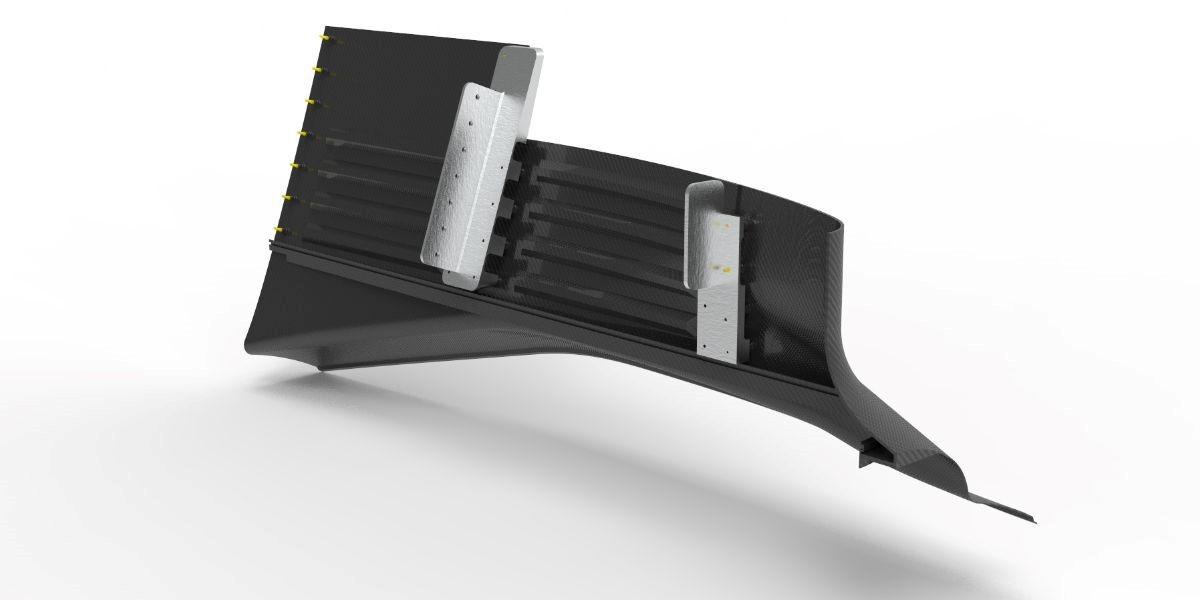

Composite Structures Design Update

This month we have been investing in our composite structures design team. They have been working on a number of projects in both the marine defence and aerospace markets.

We are also teaming up with some composite manufacturing companies to allow our end customers to have a complete turn key design and make service.

We hope to report more on this in our August / September newsletter!

Development of Hydrogen Fuel Cell Test Equipment

Our engineers have been continuing their support to the design and development of a suite of next generation fuel cell test stands. Our involvement has included developing bespoke thermo-fluid analysis tools, mechanical design of pipework, heat exchanger and instrumentation systems as well as thermal structural analysis to predict thermal expansion rates and resultant component stresses.

Our multi-skilled design team has been able to run three separate, but linked projects concurrently and recently passed several key design milestones. Our ability to link and work across multiple different design and analysis disciplines provides our customers with an efficient and comprehensive service.

New Starters at Frewer Engineering

This month Frewer Engineering welcomes Hrishi Dave to our team.

Rishi joins us from Bath University where he has been studying Aerospace Engineering.

Hrishi is currently supporting two of our projects, the first being the design of a new compressor test facility and the second, digital twin modelling of process plant to ascertain the impact of changes to improve the client’s carbon footprint.

This month Frewer Engineering also welcomes Irene Bermudo Baguena to the team. Irene joins us from Cambridge University (Pembroke College) where she is studying for an MEng.

Irene is working in our Advanced Engineering design team who are working on a complete compressor development test rig which will be used to develop future compressor aerodynamic blade and complete internal aerodynamic profiles.

The work is aimed at improving the overall performance of compressors in general.

Business Update

As can be seen from a number of our previous newsletters, we have been expanding!

Significant development in our engineering teams across the board has been completed:

New staff have joined us bringing our total engineering team to 28 with more set to join us later this year.

With a mix of highly experienced and young developing engineers, we believe we have greater strength in resourcing larger and more complex projects.