Latest News June 2022

Welcome to the Frewer Engineering latest news June 2022.

This month’s edition includes updates on a selection of our capabilities, including, combustion test equipment design, composite structural optimisation, project management and more. In addition, we showcase some of the external events, STEM outreach and charity work our team have been involved with!

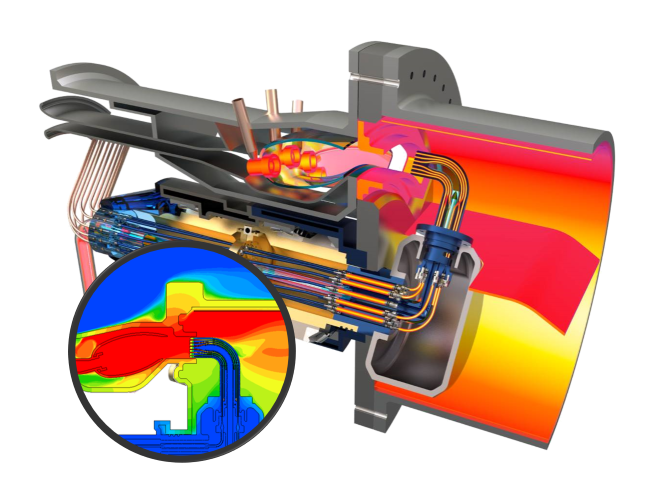

Combustion Test Equipment

Here at Frewer we are well versed in the design of test rigs for combustion testing, in particular aero-engine combustion testing. The challenge with designing this equipment is managing the extreme pressures and temperatures of the combustion environment. Our multi-disciplined team combine structural, thermal and fluid conditioning assessments to provide our customers with test rigs that are fit for purpose and meet stringent regulatory requirements. In addition, we often implement advanced mechanisms to allow for accurate analysis of combustion by-products, further complicating the design process. Our team are experts in the design of equipment and mechanisms that must withstand harsh environments whilst maintaining accurate positioning and reliability.

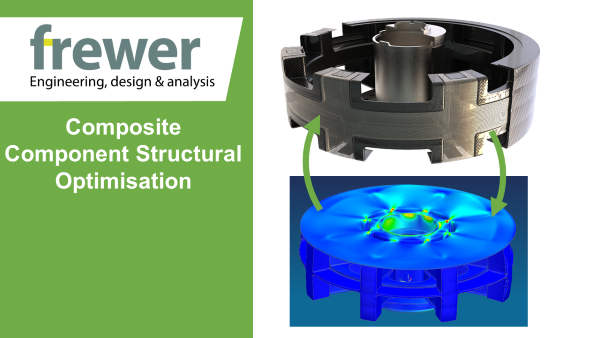

Composite Component Structural Optimisation

Our composites specialists are able to integrate both CAD and Finite Element Analysis (FEA) to efficiently optimise structures for desired parameters such as strength, stiffness and weight. In the video above we demonstrate this process on a complex multi-material belt drive system, highlighting the different techniques that can be used to optimise the design. This particular component required significant optimisation to meet the strength and stiffness requirements for accurate belt drive operation, whilst also meeting stringent weight limits for low inertia. In addition, parts of the finished component were used as tooling surfaces for the composite construction!

Project Management at Frewer Engineering

In our statistical sample of two, there is a 100% correlation between formal Project Management qualifications, and doing great work for charity!

Daniel Green (upper images) is a fully qualified APM Project Manager and Lead Engineer with Frewer Engineering, having been with us since 2016. Dan currently runs some of our larger and more complex design development projects and is adept at managing agile development processes, allowing designs to be substantiated at pace, while maintaining appropriate control of risks throughout. Demonstrating similar pace, Dan recently completed his first Marathon in a little over 4 hours, whilst raising funds for the British Heart Foundation!

Similarly, Kristian Mahon (lower images) is a skilled Fluid Dynamics Specialist and qualified Project Manager for Frewer Engineering. Kristian recently completed a walking challenge equivalent to Land’s End – John O’Groats for the Meningitis Research Foundation, over 1400 miles in 111 days, 2 million steps and many calf cramps later!

Donation pages for Dan and Kristian can be found below – please give generously if you can!

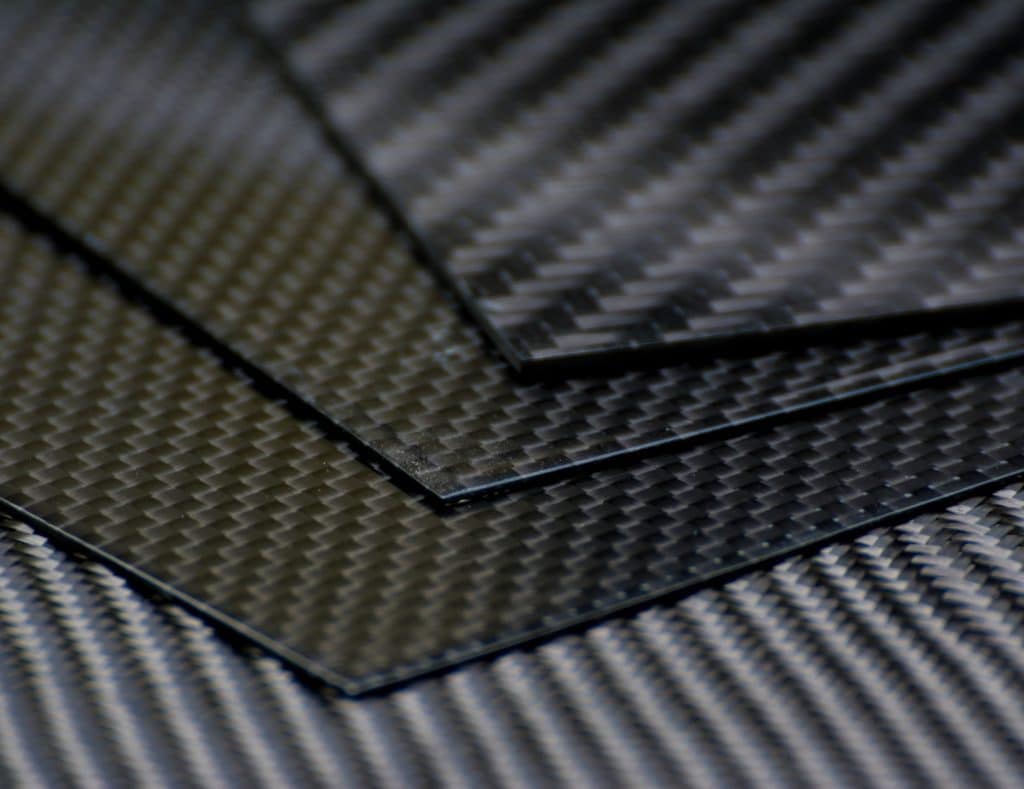

Repairing Composite Components

At Frewer Engineering, as well as designing composite components from concept level to full manufacturing detail, we are also involved in the repair of existing composite components. Our team are experienced in specifying pre-repair machining and inspections and designing optimal repair layups to be applied to the damaged area, including structural justification. We also provide detailed repair scheme drawings and support to manufacturing where required. Composite repairs can be required due to a variety of reasons, here at Frewer we have the expertise to ensure the integrity of such repairs, meaning customers parts can continue to be used, reducing costs, timescales and waste.

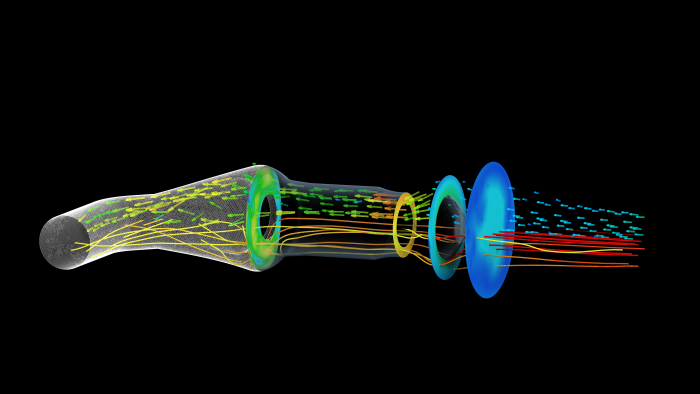

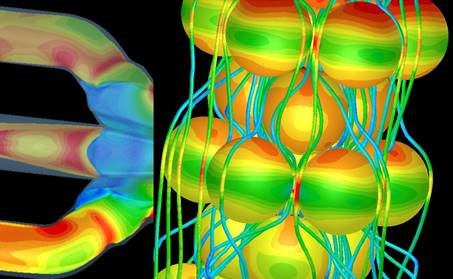

Air Presentation & Flow Management

Our team have been using computational fluid dynamic (CFD) analysis to investigate flow uniformity within an aero-engine test rig. They have modelled the air flow within the rig, using a range of visualisation techniques including contours, streamlines and vector plots to qualitatively assess the condition of the flow. We were then able to develop user defined variables, such as a flow uniformity index, to provide a quantitative comparison of the flow condition at different locations. This allowed us to determine how potential rig geometry changes would influence the flow condition at these positions. The work has provided us with a good understanding of how the flow uniformity can be influenced by even small changes to the rig design, informing future design development.

CompositesUK Hydrogen Conference

Frewer Engineering presented at a CompositesUK Hydrogen Showcase Event at the University of Warwick in late May. The company was represented by Simon Apsley and Cameron Abercromby, with a joint presentation, alongside manufacturing partners CCP Gransden of Ballygowan, Northern Ireland. Simon presented on novel high-pressure hydrogen tank shape designs, intended for favourable packaging into vehicle platforms, mirroring the ‘skateboard’ battery pack design that has been adopted for electric vehicles by many automotive manufacturers. Our presentation proposed an interchangeable energy source within the vehicle, switching between batteries, or a combined H2 tank, fuel cell and smaller battery combo, within the same flat space envelope, without compromising on the gravimetric efficiency of hydrogen storage. For further details, please get in touch with our Composites team to find out more!

CFD and Thermal Modelling Capability is Growing!

Frewer Engineering is bolstering our established CFD and thermal modelling capability, using CFD codes such as SC-flow and Star CCM. More recently we’ve been using STAR and object-oriented Python coding to represent advanced flow networks, on behalf of our customers. We are developing digital twin models which solve both steady state and transient conditions through complex networked systems. Our models are validated against existing plant, before using the software as a design tool in the development of similar higher power systems. We are proud to be supporting the UK Hydrogen Economy in these projects, backing the aims of Net Zero.

Bottle Rocket Scientists – STEM event

This month the team organised and ran a STEM event at a local school, helping children to build and launch bottle-rockets on the school field! Over the course of the week our engineers delivered lessons, teaching the pupils about the different types of forces and how they apply to the bottle rockets that were subsequently built and launched. With 240 children, 80 rockets, 160 launches, and a few budding rocket scientists in the making, I think its safe to say mission accomplished, well done team!