Latest News May 2023

Welcome to the Frewer Engineering latest news May 2023.

This issue reports on two of our engineers who met with our new King, on his first public engagement at the University of Cambridge (Whittle Laboratory)!

The Frewer Team meets our new King!

Last week, some of the team had the honour of being invited to the breaking-ground ceremony for the new Whittle Laboratory at Cambridge University. The new lab will be the UK’s first Disruptive Innovation Laboratory for sustainable aviation and energy, with the high-speed rotating test rig currently being designed by Frewer Engineering sitting at the heart of it.

The team spent the day learning about not only all the new technologies that would be incorporated into the facility, but also all the current key research being conducted at the existing lab.

The project’s importance was highlighted by none other than His Majesty The King performing the breaking ground ceremony, on his first public engagement post coronation!

Support to manufacturers following Digital Twin Modelling

Here at Frewer we continue to support our customers in the development of equipment for hydrogen fuel cell testing. Our team are supporting in the areas of digital twin modelling, to specify key components within the system. We are combining this with advanced 3D CAD design of the complex, tightly packaged arrangements and feeding back into the digital twin analysis to check against performance criteria. A key area we continue to promote across our projects is close working with manufacturers, to ensure the design meets its functional requirements but also leads to efficiencies where possible in manufacturing. We are engaging in regular Design For Manufacture (DFM) reviews to ensure that our designs are as simple as possible to build, taking advice from manufacturers on their needs during the manufacturing and assembly stages.

Looking to the future at the sustainable skies summit

Last month Frewer Engineering supported the 2-day Sustainable Skies World Summit which showcased some of the aviation industry’s latest efforts in meeting the International Civil Aviation Authority’s (ICAO) commitment to net zero – an endeavour very much aligned with our Mission Statement at Frewer Engineering.

The global summit event was organised by Farnborough International, in partnership with the Sustainable Aviation Coalition, and showcased the latest developments in sustainable aviation technology. The event included high-level keynote speakers and a forum discussing how industry can move in earnest from goal‑setting to implementation of its net zero strategies.

The event highlighted opportunities for the next generation of engineers and young people who will make Jet Zero a reality, and address the future workforce challenge.

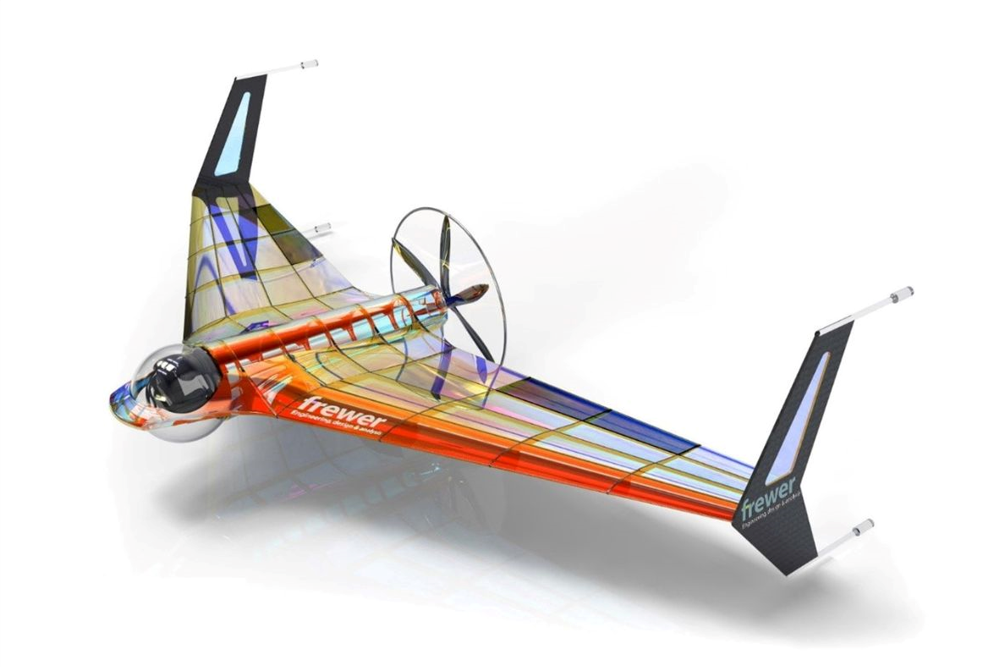

Stealthy alternative to quadcopter sureveillance drones

Frewer Engineering has an inventive and agile workforce, adept at coming up with new ideas to solve the evermore complex problems posed by our customers. The concept above answers the question of how to improve battery life in a reconnaissance camera drone over its power-hungry quadcopter counterparts.

This vehicle starts out pointing vertically skyward, resting on four legs at the winglet tips. The motor is ‘overclocked’ temporarily to lift the vehicle and transition quickly to horizontal flight before the motor can overheat. Landing presents a slightly greater challenge, with a more extended time at peak power, but the same principle applies; the control system brings the platform into a brief controlled hover for landing.

The key advantage of this design is the low noise signature when in horizontal flight. The platform can be small, lightweight, and very quiet, circling a target to gather high-quality imagery in a highly stealthy manner. The only significant ‘drone’ like noise will be emitted on take-off and landing, which can be done away from the target.

Our commitment to agility and flexibility

Whatever your views on remote and flexible working, one thing is certain: the demand for flexibility is increasing.

By embracing remote and flexible working, we can provide seamless support regardless of geographical boundaries. Equally, it caters to our workforce’s diverse set of personal responsibilities and commitments, including those with young families. By offering flexibility, we empower the team to manage work alongside their personal commitments, fostering a happier and motivated workforce.

In parallel, we acknowledge the continued need for face-to-face communications and in-person collaboration. This is why we continue to maintain full offices and meeting rooms at our headquarters in Jayes Park, Dorking. This site includes key facilities such as a 3D printing workshop space and a Virtual Reality (VR) suite. We encourage our customers to make use of these facilities where possible to support live projects.

Get in touch to learn more about the remote and in-person capabilities we offer.

High temperature exhaust Nozzle now in service

Our high temperature nozzle design for the development of future greener gas turbines enters service!

Our complete turnkey service is a regular feature and involves supporting our clients during manufacture with design changes due to unforeseen issues such as material availability changes. Our design team are acutely aware of Design For Manufacture (DFM), which we consider throughout our projects, working closely with manufacturers to avoid issues further down the line.

Currently our design team are completing refresh training in GD&T to better capture the design intent in manufacture and assembly.

All design staff will be obtaining certification to the ASME Y14.5-2018 standard. This will ensure our designs are dimensionally controlled through manufacture, increasing the efficiency of the DFM process.

New Starters Brings our Team

to a Total of 30!

In the coming months we have seven new members of staff joining our team! The new starters will be bolstering the following departments in our engineering consultancy service:

- Computational Fluid Dynamics (CFD)

- Mechanical & Structural Design

- Detailed Design

- Thermal and structural analysis (FEA)

Keep an eye out for more detail on our new members in the following issues of this newsletter…