Latest News November 2020

Welcome to Frewer Engineering’s Latest News November 2020.

Significant company investments are reported in this newsletter, as well as updates on our live projects and staff training!

We hope you enjoy the read.

Investing in our business for 2021

Design of future gas turbine combustion test equipment

This area of our business remains highly active even during Covid 19! Our team is busy working on future environmentally friendly gas turbine engines for aerospace in the following areas:

- Advanced combustion research equipment to improve the environmental performance and efficiency of future military and civil gas turbines.

- Hot Nozzle design, again with research into increased performance and noise reduction.

- Future very large scale fan blade development to facilitate much larger bypass ratios and hence lower noise and increased range.

Further to the above, our engineering team have in excess of 25 years of combustion equipment design experience on both full annular and sector rig combustion test projects.

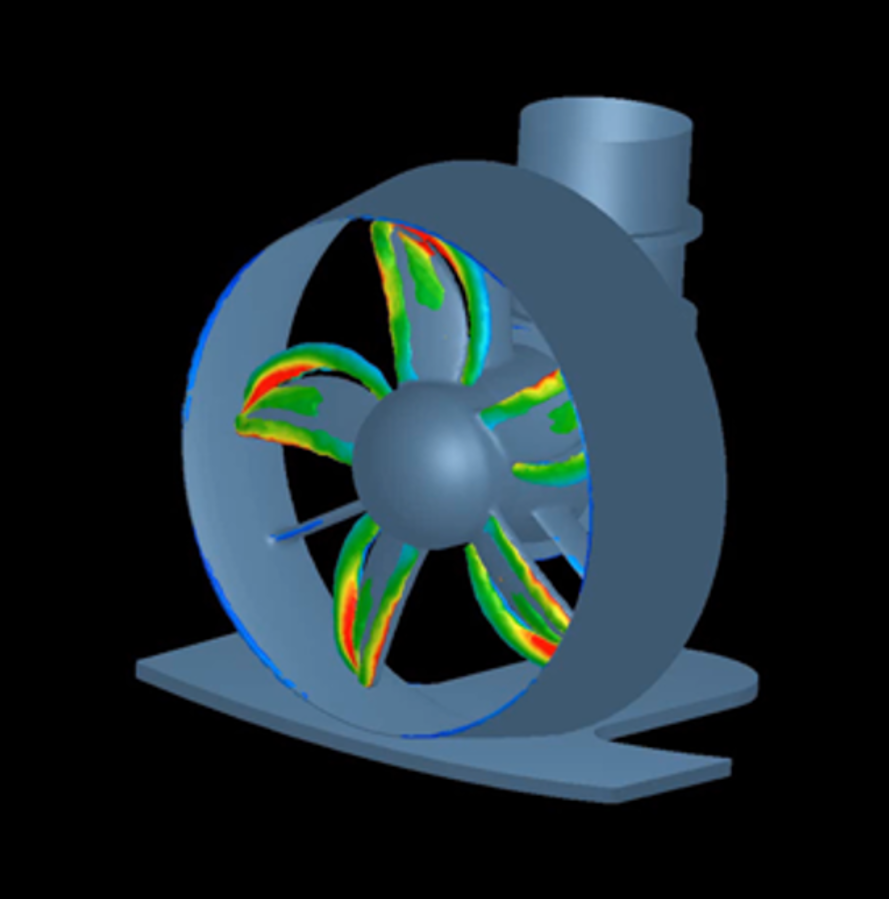

CFD & Advanced Analysis

Adding to our existing CFD software tools (MSC scSTREAM & scFLOW), our engineers are getting to grips with Open Foam CFD and shortly will be fully utilising SIEMENS STAR CCM+.

We are also beginning to use MSC APEX for advanced finite element model building. This new MSC software tool is developing rapidly and our team are on board to reap the benefits of the time savings this analysis tool can bring to complex FEA models. MSC APEX is particularly effective in the area of geometry clean up often on complex aerodynamic surfaces, such as, gas turbine blades, aerofoils and aerodynamic panels. Again this provides a time and cost saving to our customers.

Please do get in touch if you have any CFD and/or Advanced Analysis requirements. We offer specific analysis only packages as well as a complete “turn-key” Design & Analysis capability by integrating our three company divisions.

Information Technology IT Investment Update

Our next targeted investment is in new CFD & thermal analysis tools. This investment will give us the ability to pick the most appropriate tool for the analysis task requested by our customers. Two tools currently in the pipeline are STAR CCM+ (SIEMENS) and OPEN FOAM (Freewhare). This investment is in response to huge customer demand for these services.

Two new high specification workstations are being procured to allow us to solve large analysis models more efficiently, especially in the fields of CFD and thermal analysis. Furthermore, the new workstations will bolster our efficiency in the design and analysis of gas turbine blades and blade discs.

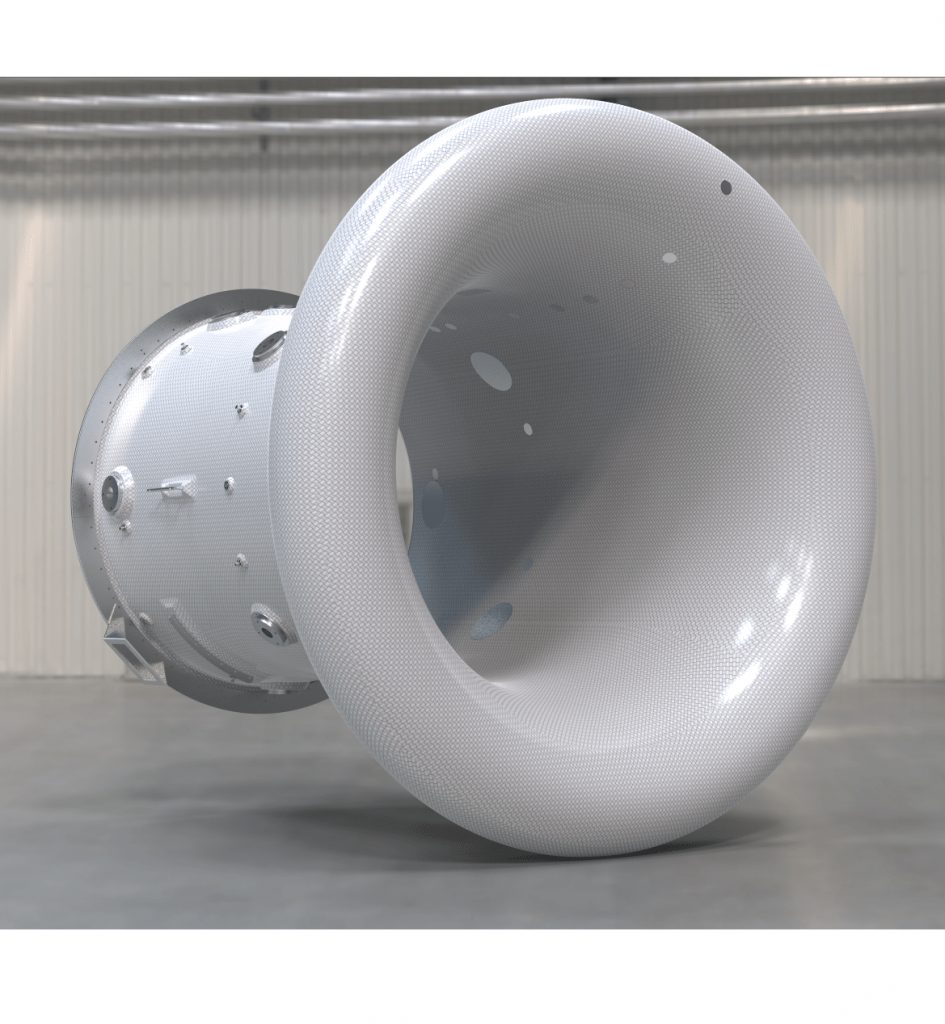

Advanced Composites

Marine Defence Sector

October has been another hugely productive month for Frewer’s Advanced Composites division. As our 2-year marine defence project enters the detail design phase, we have been working closely with our manufacturing partner, Norco, to optimise the design of two geometrically critical composite mast structures.

Subjected to severe loading and environmental conditions, our FEA-derived laminate designs are critical to performance, yet, we are only too aware of the equal importance of meeting practical manufacturing requirements.

Working hand-in-glove with Norco has seen huge strides forward in bringing these defence-critical components to reality. Design for manufacture (DFM) is a key service we provide across our business, leading to optimised cost-effective solutions for our end customers.

Business Update

As we continue to grow we have now sectorised our business into three divisions as listed below:

Advanced Engineering Division

Advanced Composites Division

Advanced Analysis Division